- Upgrade the CNC routers you already know and trust.

- Minimize disruption & time to replace your CNC router.

- Easy program transfers, no need to rewrite G code or post-processor changes.

- Invest in modern capabilities to enhance productivity.

- Keep competitive edge with industry advancements.

- Receive free support for the life of the control.

WE’VE UPGRADED THESE BRANDS AND MANY MORE!

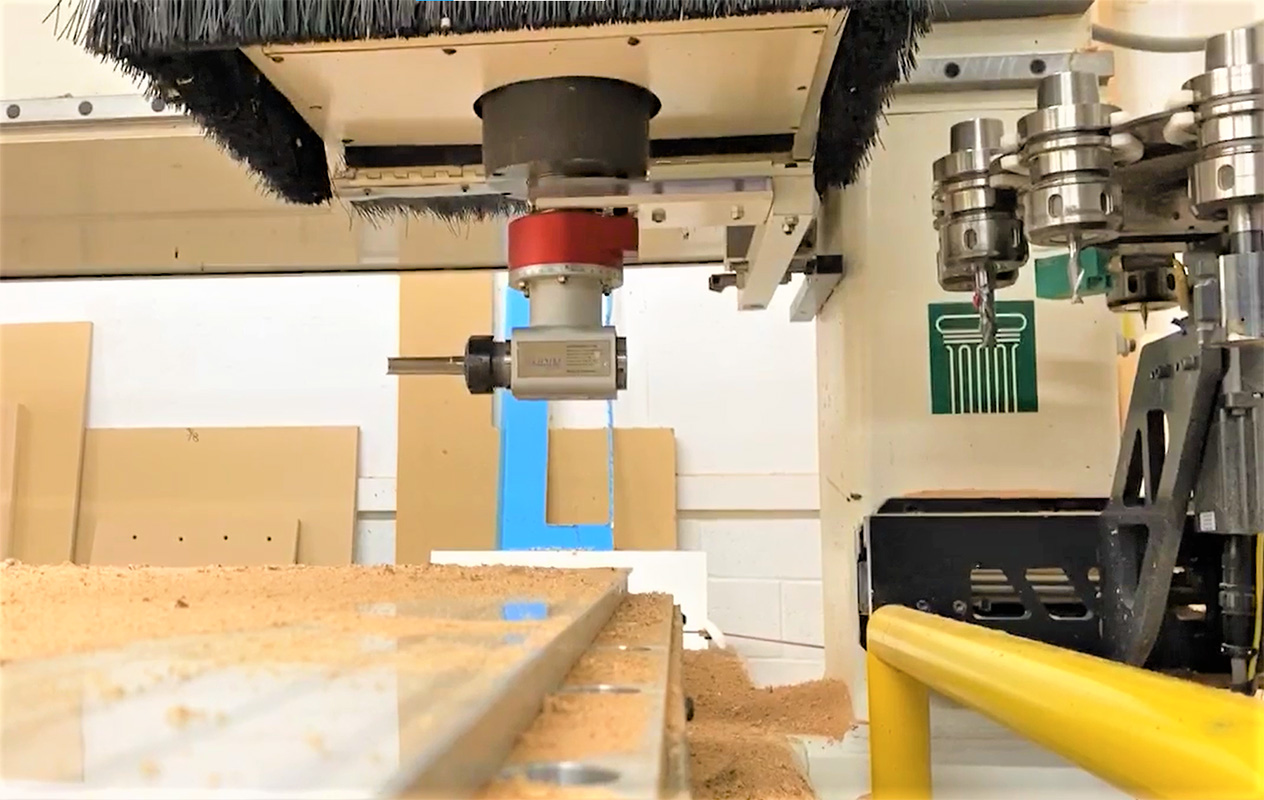

What is the process?

Discovery and Assessment:

First, we schedule an initial discovery call to understand and assess the current state of your CNC router. We gather information on the machine such as make, model, and other specifications.

Custom Solution Proposal:

We develop a tailored solution to your machine and send a proposal outlining the CNC retrofit solution including control systems, motors, drives, and any additional components.

Approval and Scheduling:

Once approved, we schedule the CNC router retrofit project, being considerate of operational timelines and constraints.

On-Site Installation:

We make quick work and send our expert install team to your facility for the installation. A typical install takes no longer than 1-week.

Testing and Training:

Our install team tests your CNC router retrofit to ensure all components function seamlessly and provide comprehensive training for machine operators on the new system.

We provide continuous remote support for the life of the control to address any queries or issues and keep you in production for years to come!

OPTIMIZING YOUR WORKFLOW

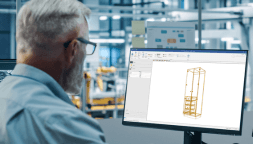

USE YOUR EXISTING CAD/CAM SOFTWARE

Use Your Existing CAD/CAM Software

• No Post-Processor change – Control works with all the popular CAD/CAM software.

Compatible with CabinetVision, SolidCam, Autodesk AutoCAD, Enroute, Fusion 360, BobCad/CAM, Vectric, Rhinoceros, SprutCAM, MeshCAM, CamBam, and many other brands.

pERSONALIZE yOUR CONTROL SCREEN

Personalize Your Control Screen

Common Router Buttons Include:

– Vacuum On/Off

– Dust Collector On/Off

• Make as lean or as advanced as you need it.

• Lock users out of specific screens or tabs.

WIRELESSLY CONTROL YOUR CNC ROUTER

Wirelessly Control Your CNC Router

- Jog the machine, set your zeros, control your feeds, speeds, start & stop the machine

- Wirelessly increase mobility, safety, and accuracy

- Program 4 custom function buttons tailored to your production processes

- Magnet allows you to easily store on the controller or any nearby metal surface

A LIFETIME OF CNC ROUTER SUPPORT

Reduce Your Training Time

- You’re supported for the life of the control, we never leave you hanging.

- Resolve technical issues quickly and efficiently, reducing downtime and increasing productivity

- Access to dedicated experts who can provide comprehensive support

- Eliminates travel costs associated with on-site visits

CNC ROUTER RETROFIT UPGRADE OPTIONS

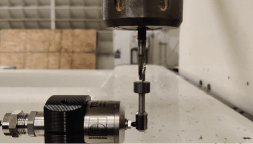

TOOL SETTER

Automatic Tool Setter

- Effortlessly measure tool length or height automatically

- Easily detect tool wear or breakage

- When cutting material that wears tools rapidly, quickly re-measure tool length between jobs

- Restart work fast after replacing a tool manually or using an automatic tool change

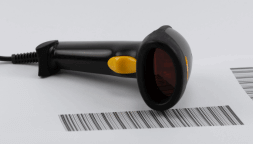

bARCODE SCANNER

Barcode Scanner

- Load cut files easily with a barcode scanner

- Less chances of operators loading the wrong files

- Anyone can load the material, scan the cut file, and start the CNC router

- Create an easier process for operators to ensure accuracy with every job

JOB QUEUE TOUCHSCREEN

Job Queue Touchscreen

- Make the operator’s job even simpler with access to the job queue right at the control

- Manage your ERP or MRP system from the control

- Paperless viewing of cut files and jobs makes it quicker to communicate

- Eliminate extra steps and make production easier and faster

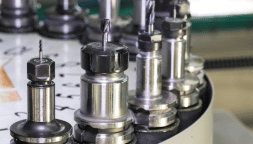

AUTOMATIC TOOL CHANGER

Automatic Tool Changer

- Enhance efficiency by automating the tool changing process, reducing manual intervention and optimizing production time.

- Easily switch between various tools during a job without interrupting the machining process

- Reduces the risk of injuries of manual tool changes and enhances workplace safety

PROUD ASSOCIATION MEMBERS OF:

Documentation

Router Control Operating Manual

2000 Series CNC Control HMI

Example Electrical Machine Schematic

CNC Control Model and Drawing

Mounting Options Models and Drawings

GET STARTED!

REQUEST A QUOTE

ARRANGE YOUR INSTALL

RUN WITH CONFIDENCE

Call me at (573) 368-7399 or enter your name and number here and I’ll get back with you within a few business hours.