23 Jun Step By Step CNC Retrofit – The MachMotion Expert Installation Process

Step By Step CNC Retrofit – The MachMotion Expert Installation Process

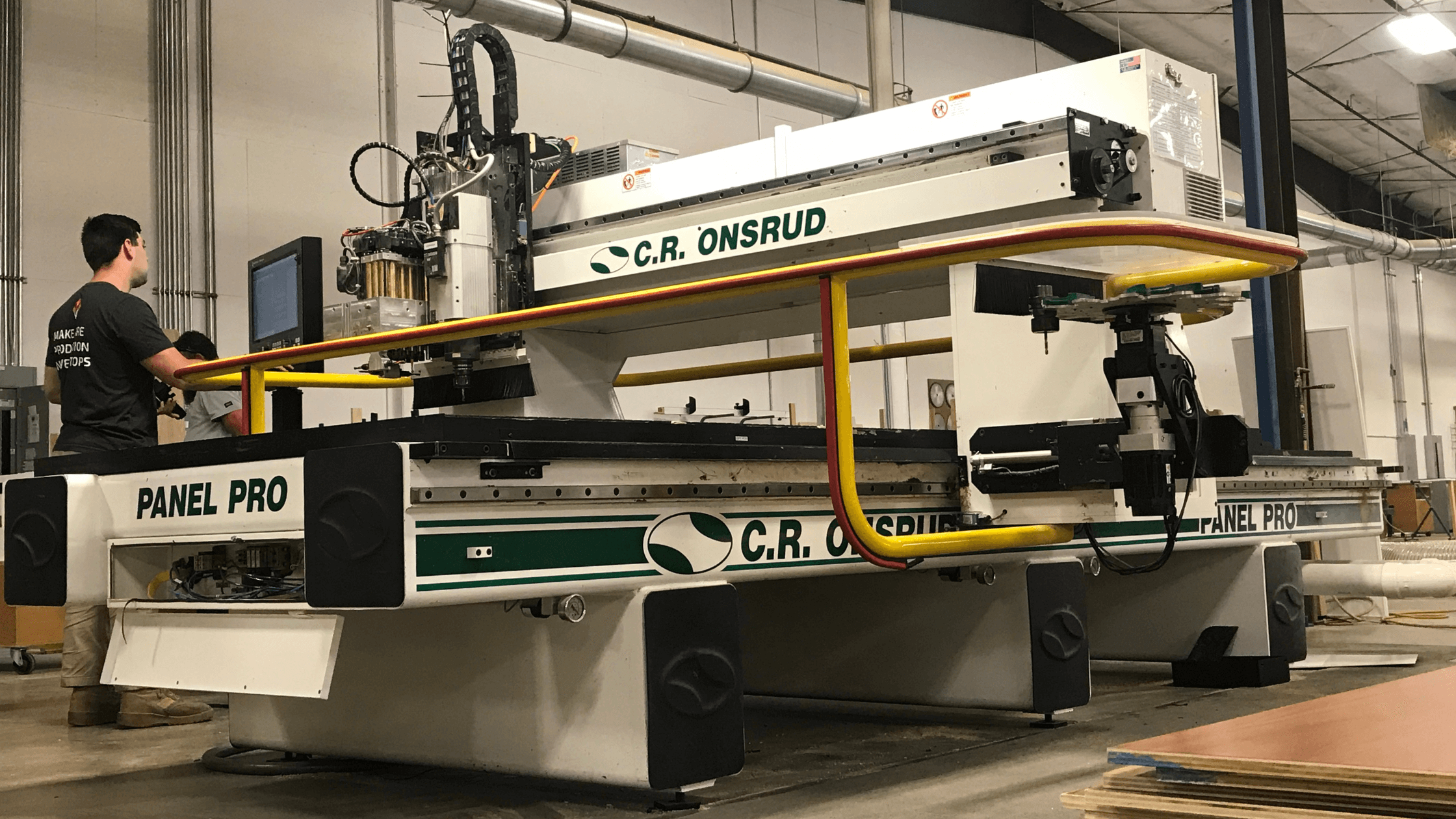

We take the mystery out of CNC retrofits and explain our process step by step for installing a controller upgrade on a C.R. Onsrud Panel Pro CNC Router!

Scheduling The CNC Retrofit

The MachMotion install crew headed to Bassett, Virginia to do a CNC retrofit on a C.R. Onsrud 145G16D Panel Pro CNC router for Sleepsafe Beds. At Sleepsafe Beds, they specialize in manufacturing Durable Medical Equipment (DME) beds that provide a solution for caregivers that would prevent falls and entrapment for individuals who have challenges with extremely active special needs. They utilize many different pieces of CNC equipment to complete different steps in their processes and rely on their CNC routers for cutting wood panels for the bed frames.

When Sleepsafe Beds started encountering issues with their C.R. Onsrud 145G16D Panel Pro CNC router, they began looking for reliable solutions to keep their production going. What happened was the older OSAI controller on the Panel Pro started experiencing different faults they couldn’t clear, causing many headaches. Eventually, the OSAI controller had died completely and they were no longer able to operate their C.R. Onsrud CNC router. When they found MachMotion’s CNC upgrade solution, they decided to do a CNC retrofit with a turnkey install from MachMotion’s expert installation team. Read on to understand the full process of a CNC retrofit and how MachMotion has redefined what it means to get a CNC retrofit!

CNC RETROFIT PROCESS

Decommissioning & Mounting New Hardware

All of our CNC controller retrofit packages are designed, assembled, and tested at our facility before installation begins. Once we have all the new components quality checked & shipped out from our facility, we show up on-site with a full install crew. Our team begins the process of the CNC retrofit by shutting off the power and removing the covers. Then, we carefully remove all the old hardware components. This includes the old controller wires, servo motors and drives, as well as the electrical panel. When we remove the wires we are careful not to cut the cables, unless we are 100% sure they will not be needed for the new control system.

Electrical components will inevitably age and break down over time. CNC machines can be evaluated prior to installation in order to determine if they have any hardware that can be reused. If the other hardware is as old or even older than the controller, we recommend replacing them for best performance results. Once all the old hardware is removed, we then go ahead and install all the new hardware and reconnect the wiring.

Wire I/O (Inputs & Outputs)

Then, we take the next step to identify all the I/O (inputs and outputs) that we plan to reuse. In this case with SleepSafe Bed’s C.R. Onsrud 145G16D Panel Pro CNC router, we were able to reuse everything. Some examples of what we reused were the backing pressure sensors and the emergency stop bumpers on this machine. We adapted all the old pneumatics, the draw bar, and the drill bank and reincorporated them into the new controller system.

Wiring & Set-Up

Next on the list we focus on wiring & set up. We run all the motors wires on the machine to the appropriate VFD or motor contactors. We adapted all the old wiring that we reused and updated our wiring diagram for the Panel Pro CNC router. This allows us to leave a complete electrical schematic with our customer when we’re done with the job.

Power Up

After wiring the cables and the hardware set-up is complete, we are ready to power up the C.R. Onsrud Panel Pro router. The installers go through our preliminary checklist to make sure the basics are good, such as the x, y, and z motions of the machine. We do our servo tuning if we need to that day and help make sure everything is running smoothly.

Software Set-Up

Once our install team confirms the CNC router is moving, we get started with the software set-up. We set-up the axis directions, overtravel limits, units, soft limits, any extra spindle motors and IO. We work on recalibrating the machine, entering all that data we gathered like ball screw pitch and gear ratios to make sure the machine is running accurately.

Get Back Into Production

As soon as the software set-up is completed we verify all bolts have been torqued and all covers have been replaced. We then integrate the system back into production. Our team gets the g-code files from the customer and loads everything on to the machine. Then, we make some test parts to make sure everything is cutting & running properly. Once we confirm, we move on to the last and final step in our CNC retrofit process!

Training Your Team

Training your team is the final step in the overall CNC retrofit process. We go over where all of the basic buttons and functions are. We work closely with your team to make sure they can operate the machine on their own. Our team is very knowledgeable and can answer any questions your team has. If your operators do require additional help once we have left the install, our remote support team is always ready to help! We make it easy for our team to remotely login and see your screen. We can walk you through your questions and get you back up and running quickly.

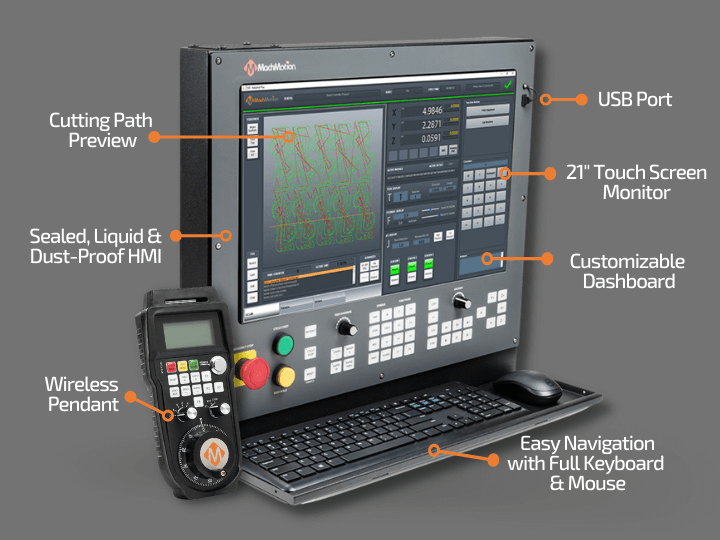

Standard CNC Control Package comes with:

• 21″ Touch-screen CNC controller

• Wireless pendant

• Pre-wired & labeled electrical panel

• Yaskawa servo drives & motors

• Control mounting & stand options

• 1-Year Warranty

Get Back In Production With MachMotion!

SleepSafe Bed’s was able to keep the machine they already had an upgrade to a working, reliable control. They are now able to get their C.R. Onsrud CNC router back into production! Our on-site installation team can install a turnkey controller upgrade for your CNC router with minimal downtime & disruption. The MachMotion 2000 series controller is really easy to learn and navigate. The controller’s PC-based interface makes it intuitive to use for beginners as well as machinists with years of experience. With the freedom to customize your on-screen controls to utilize your most-used functions. If you have a CNC machine you’d like to retrofit or that is experiencing issues with an aging controller, please use the form below to connect with us and see what we can do for you.