12 May Wish Your CNC Problem Was Worse

Why You Should Wish Your CNC Problem Was Worse

Why should you wish your CNC problem was worse than it already is? That seems like the counterintuitive thing to do, right? You should wish it better, but then you would just be wishing. The mere definition of the word “wish” is to want something that cannot or probably will not happen. So why would you wish for something worse instead of better? The reality is, if it’s bad enough that someone will take action to do something about it, it may actually make your CNC problem better than it is now.

We hear all the time from customers that their CNC machines aren’t “broken enough” for them to do anything about it just yet. You found someone local that can temporarily fix this or that to keep the machine running or you have a backup control on the shelf from an auction won on eBay. You are doing just fine until you aren’t anymore. Once it completely stops working and halts your production, the lead manager goes into full panic mode and starts Googling what to do or who can help. Now, fighting the clock and your customer’s deadlines you have very few options that can solve the problem quickly.

A new machine would be great, but the lead times are 6-9 months out and you can’t afford to be down that long. You can look at a used machine, but at that point, you’d still be down longer than expected and you have no idea if you’re just investing in someone else’s headache. You contact your guy who “knows a guy” that could possibly take a look and get it back up and running, but he can’t guarantee that he’ll leave you with a running machine. What other options do you have left?

You’ve heard of a CNC retrofit, but the word alone is terrifying. You’ve heard awful stories from other manufacturers like yourself that ended with their CNC machine in pieces, and just as lifeless as it was before they called anyone for help. They spent so much money to try and keep their machine but were left in the dust. Does this sound familiar to you? If it doesn’t, you’re one of the lucky ones. If it does, then you’re definitely in the right place. We’ve heard these horror stories of retrofits that have gone wrong too. This is why we approach CNC retrofitting differently.

You should wish your CNC problems were so bad, that someone would have to take action to do something to resolve the issues.

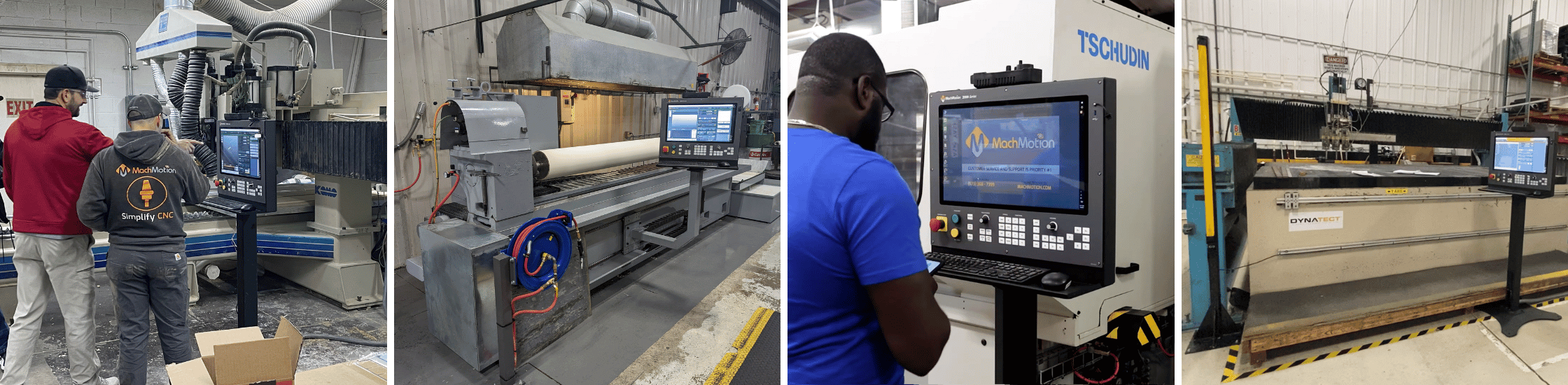

When you call MachMotion for help with your CNC machine, you get to talk to a real person, every time. Our team is staffed with experts that understand the struggles of obsolete controls and unplanned downtime. We know how your machine works and what needs to be done to get it back into production. There are no guessing games when you’re partnered with us. Once we finish the engineering and building your system, it just takes you offline for one week with a professional turnkey installation. Our production-ready guarantee means that we leave you with a running machine.

By acknowledging the severity of your current CNC problems and challenges, you open yourself up to the possibility of a much better future. So maybe it’s time to stop wishing, for better or worse, and take the first step to optimize the CNC machines you have. Don’t wait for circumstances to worsen. Instead, take charge and actively pursue a brighter future for your CNC operations. Call us at 573-368-7399 or fill out the contact form below to see how you can take action and upgrade your CNC machines before disaster strikes.

If you enjoyed reading this, be sure to check out our other articles like CNC Controls – If It’s Broke, Don’t Fix It Watch our YouTube channel for more information, tips, and customer success stories to learn more about CNC retrofits!