31 Aug CNC Controls – If It’s Broke, Don’t Fix It

CNC Controls: If It’s Broke Don’t Fix It?

The toxic effects of doing nothing about broken CNC controls and how to put an end to your CNC controller issues.

“If it ain’t broke, don’t fix it” implies that if something, like a CNC control, is working properly, it’s probably best to leave it alone and avoid making any changes that may break it. But, what happens if it is broken and no actions are taken to fix it?

We’ve all been there: In the middle of completing a job for a valued customer and something goes wrong with the CNC control. We don’t know what’s wrong with it. We can’t get a hold of anyone from the company that sold us the equipment because they no longer support the machine (or even worse – they no longer exist). And so we try our best to fix it ourselves, Googling the problem or error code, maybe calling on maintenance to come to troubleshoot the issue. The worst part about this whole situation? The systematic issue(s) have not been addressed still and nothing has been done since the last time you experienced this issue.

Common Problems With CNC Controls

- CNC control malfunctions on power up

- Failing CNC machine motor driver controllers

- CNC control stops in the middle of a program

- CNC control has sporactic motion in the middle of a program

- Unable to clear the emergency stop or “e-stop”

- The control panel stops lighting up

- Motherboard or motion board dies

- Has Trouble/Won’t connect to the network

- I/O connection issues

- Controller unsupported or obsolete

Understanding The Struggle

If you’re suffering through CNC controller issues, it’s not worth it to wait until later to fix the problem. It may only get worse and more expensive if you do. Doing nothing can increase downtime and become costly in terms of productivity loss, efficiency losses, and other indirect costs associated with unnecessary downtime. Such as employee frustration and stress levels rising due to the lack of access to tools necessary for their job responsibilities. Failing CNC controls happen more often than we realize. Experiencing problems is one thing, but addressing and solving the issues is a whole other story.

You may think that calling for help will take too long, but time is money! The machine will continue to break down unexpectedly until properly fixed. The longer you wait, the more likely it is that your CNC control will get worse or that you will lose revenue due to machine downtime or unnecessary and possibly unfruitful service calls. We can all come together to complain about the troubles of our CNC machines and how it would be great to not have to work around for a dying control, but the truth is that there are modern, long-term solutions to get your machine in working order with a team of support staff to help when questions arise.

Taking Action: Upgrading Your CNC Controls

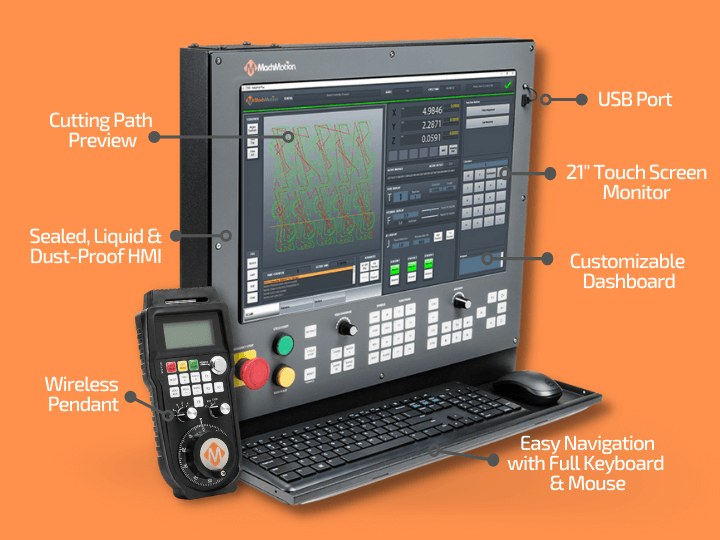

You understand the problems you’re experiencing, so how do you eliminate them for good? A CNC retrofit of your controller system can help put an end to your programming workarounds and unexpected downtime. The process takes about one to two weeks to complete, depending on size and complexity of the machine. All the old electrical components and the controller are removed and replaced with a brand new 21” touch-screen control, new motors, and a new electrical system that makes sense for your machine. We discuss your process in depth and see how we can help you turn the CNC machine you have into the CNC machine you want for the long term.

Key Benefits of a CNC Controller Retrofit:

- Increase CNC Lifecycle & Dependability

- Reduce Costs, A Fraction of the cost of a new machine

- Reduce Unplanned Downtime

- Eliminate Rigging & Transportation Costs

- Improve Performance and Precision

- Reduce Training Times with an Easy-to-Operate Controller

- Eco-Friendly

- Access to Free Remote Support

- Production-Ready Guarantee

- 1-Year Warranty on all Turn-Key Retrofits

The MachMotion 2000 Series CNC controller is equipped with conversational programming built right into the software. This enables machine operators to design and manufacture parts without having to run between their desk and the machine to transfer programs. This feature alone can help businesses to maintain a higher degree of efficiency and maximizes the return on investing in a new controller. The CNC controller can be easily serviced remotely if you need support down the road. All CNC machine controllers we ship are fully functional, fully integrated and tested systems, so what are you waiting for?

Standard CNC Control Package comes with:

- 21″ Touch-screen CNC controller

- Wireless pendant

- Pre-wired & labeled electrical panel

- Servo drives & motors

- Control mounting & stand options

- 1-Year Warranty

- Support for the life of the control

Easy Installation Options For Every Budget

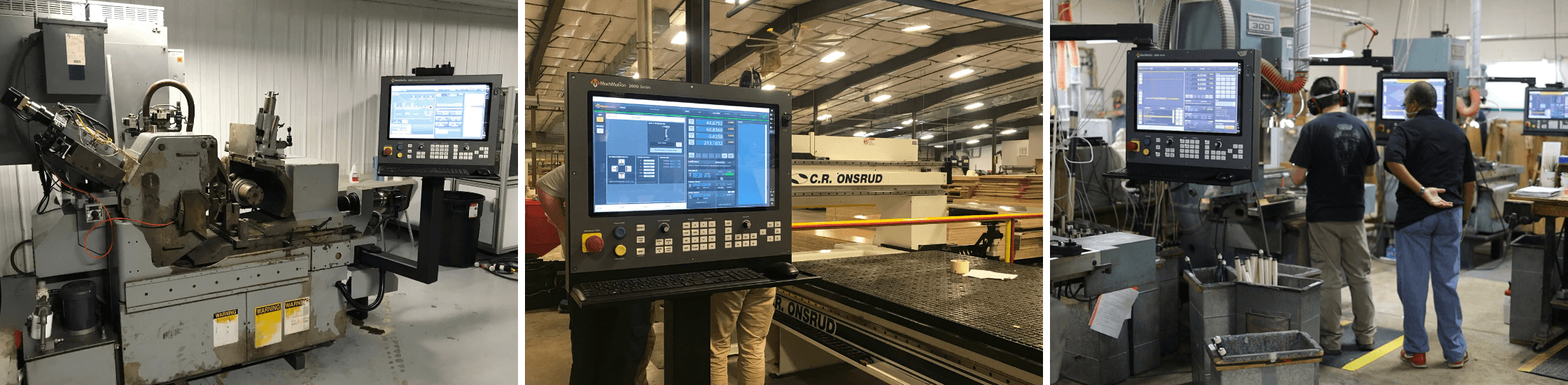

For each machine upgrade, we strive to provide the best service possible. Our installation options are flexible to meet everyone’s manufacturing needs. We offer a turnkey installation option that allows you to relax and let our expert installers do the work. This is a great option for larger machines that are hard to move. We show up on-site and complete the installation right in your facility. Alternatively, if you have a machine that is shippable, we can retrofit it in-house at our facility in Missouri and ship it back to you once it’s ready for production. We also offer a commissioning option. You can do some of the work like mounting the new controller, motors, and electrical enclosure and we will come to your facility to finish the installation and train your operators. Lastly, we offer self-installation. If you and your team have basic electrical knowledge and mechanical skills, you can install the kit on your own as well. Our remote support team is here to assist throughout the process and beyond. It’s up to you which option is right for you, and our team will support you in every step, no matter what you choose.

Talk To Real Experts With MachMotion Support

Providing world-class customer service for the life of the control is MachMotion’s commitment to making sure production never stops. When you call into MachMotion, you’ll talk to a real person, based right here in Missouri. Our team of highly-trained specialists are ready to assist you without automated systems or long wait times. You can explain what you need to someone who understands and can get you the answers you need in a timely manner. We won’t leave you hanging. Take the first step in eliminating your machine problems by contacting us today at the form below.

CNC Machine Brands We Have Retrofitted:

Flow Waterjets

Calypso Waterjets

KMT Waterjets

TECHNI Waterjets

OMAX Waterjets

C.R. Onsrud CNC Routers

KOMO CNC Routers

Thermwood CNC Routers

Multicam CNC Routers

Northwood CNC Routers

AXYZ CNC Routers

Hurco Knee Mills

Bridgeport Knee Mills

Tree Knee Mills

Hardinge Knee Mills

LeBLOND Flat Bed Lathes

American Pacemaker Flat Bed Lathes

G&L Boring Mills

Lucas Boring Mills

Pratt & Whitney Boring Mills

Cincinnati Centerless Grinders

Viking Centerless Grinders

Van Norman Centerless Grinders

Micron Centerless Grinders

Okamoto Centerless Grinders

Kellenberger ID/OD Cylindrical Grinders

Brown & Sharpe Cylindrical Grinders

Chevalier Cylindrical Grinders

& many many more!