11 Aug Waterjet Retrofit With MachMotion

CNC Waterjet Retrofit — MachMotion Takes CNC Waterjet Controllers To The Next Level

Are you experiencing unexpected downtime? It may be time for a waterjet retrofit.

Have you thought about a waterjet retrofit? CNC waterjet controllers are a critical part of any CNC waterjet. No matter what kind of waterjet cutter you have, whether it is a Flow, OMAX, JetEdge, Wardjet, CMS, Hydrajet, Calypso, Baileigh, or another brand, its electrical components are susceptible to wear. In any CNC application, the controller is a critical component for executing CNC programs, whether the material is stone, metal, glass, plastics, or even insulation. Regardless of whether you are working on small-scale projects or large-scale production, your CNC waterjet has to be in its best working condition for accurate and efficient performance.

So here’s the deal…

CNC Waterjets are not a cheap investment. Some of the lower-cost models can begin at around $100,000 and high-end waterjets can cost upwards of $1,000,000. If you’ve ever owned a waterjet cutting machine, you may have considered upgrading to a newer model for a multitude of reasons. As with any large purchase, shopping around for new machines can be an exhausting and overwhelming process.

There are so many waterjet cutters to choose from, with each having different capabilities and applications. Not to mention, having to navigate the logistics of moving your old machine out and a new one in. In some cases, buying a new CNC waterjet can be out of reach for a business that already has existing machines, but needs better technology to keep growing. What if you could invest just a fraction of the cost of a new machine and have your existing machine upgraded and running like new again?

A Reliable Waterjet Solution

It’s obvious that most businesses will not be able to afford the up-front cost of buying a brand new CNC waterjet cutter. We understand that businesses need to upgrade equipment without breaking their budgets to work proficiently. For the ambitious and industrious, there is an easy way to bring new life into your already existing CNC waterjet with a controller retrofit. A waterjet retrofit takes your existing machine and connects a new HMI control, electrical wiring and other components when necessary. By choosing this route, companies can save thousands of dollars on the cost of purchasing a new waterjet. Upgrading with a retrofit can give your CNC waterjet equipment incredible gains in efficiency and productivity to help your team keep production going!

MachMotion CNC Waterjet Retrofit

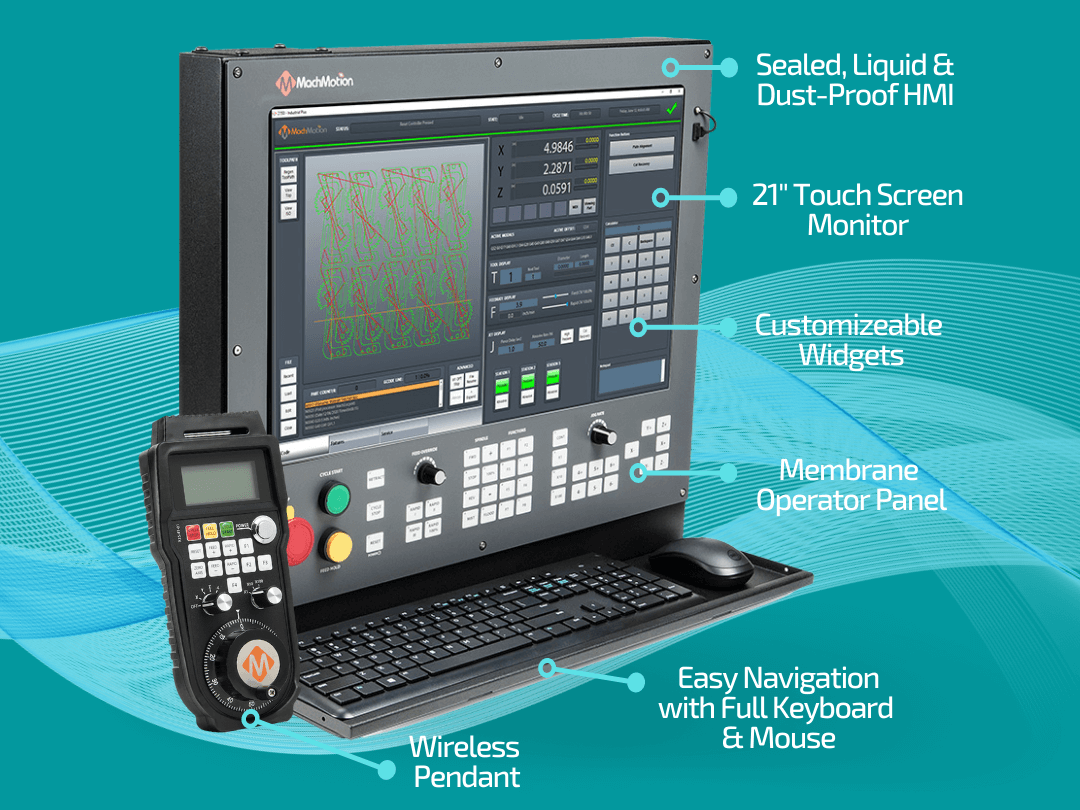

MachMotion Waterjet Controller Retrofit is a cost-effective solution that will make your existing CNC waterjet machine run like a brand new system, without the high costs of moving out an old machine and purchasing a brand new machine. Each retrofit comes standard with a new HMI control, intensifier controller, pre-wired electrical panel, and new servo and motors when needed. These enhancements help to improve your overall waterjet cutting operation while providing increased uptime and accuracy

The PC-based HMI controller is liquid & dust proof and runs on a standard Windows operating system. The intuitive Smart Conversational interface is customizable and allows you to maximize your team’s productivity. MachMotion’s 21″ touch screen control helps reduce operator fatigue from staring at small controller screens. The controller can integrate with your existing CAD/CAM programs. Compatible CAD/CAM programs include AutoDesk TruNest, Hypertherm ProNest Nesting Software, SigmaNest Nesting & Shape Library, Nest&Cut Nesting Software and many more! At MachMotion, we have seen countless instances where upgrading an old controller has saved companies money in the long run. It’s an investment well worth making for any business that depends on waterjet cutting.

MachMotion’s CNC Waterjet Retrofits Provide:

- FREE Remote & Phone Support for the lifetime of the control

- 1-Year Warranty on Controller

- Production-Ready Guarantee (on all MachMotion installs)

- Intuitive Smart Controller for fast training

- Preservation of existing machine(s)

- Maximized efficiency

- Improved machine performance & reliability

- Reduction of unexpected machine downtime

- Cost-savings and the lead time of purchasing a new waterjet

- Financing options to help you get what you need

Interested In An Waterjet Retrofit for Your Machine?

If you’ve been thinking about waterjet retrofit, look no further! The retrofit process with MachMotion is reliable, quick, and cost-effective. We start by requesting photos of your machine to adequately analyze your machine. We ask for details like brand, model, how many axes, machine voltage, horsepower of the spindle motor, and any other information to factor in to estimate costs. Then, our sales engineers will walk you through what upgrade options work best for your facility and machine. We get you an estimate based on the discussion and go from there. It’s that simple! Check out the 9 Benefits of a CNC waterjet retrofit to learn more about how a retrofit can help your waterjet cutter.

CNC Waterjet Retrofits are great for brands like:

AIM Master Jet Saw

AV

Bystronic Waterjet

C&G Systems

CMS

Calypso

ESAB

Flow

Hornet

IWM

Jet Edge

KMT

Knuth

MachItech

Mitsubishi

MultiCam

Nova Range

Omax

Romeo Engineering

TECHJET

TECHNI

TeCnocut

WardJET

& more!