27 Feb OSAI Alternative: MachMotion Redefines CNC Machine Controls

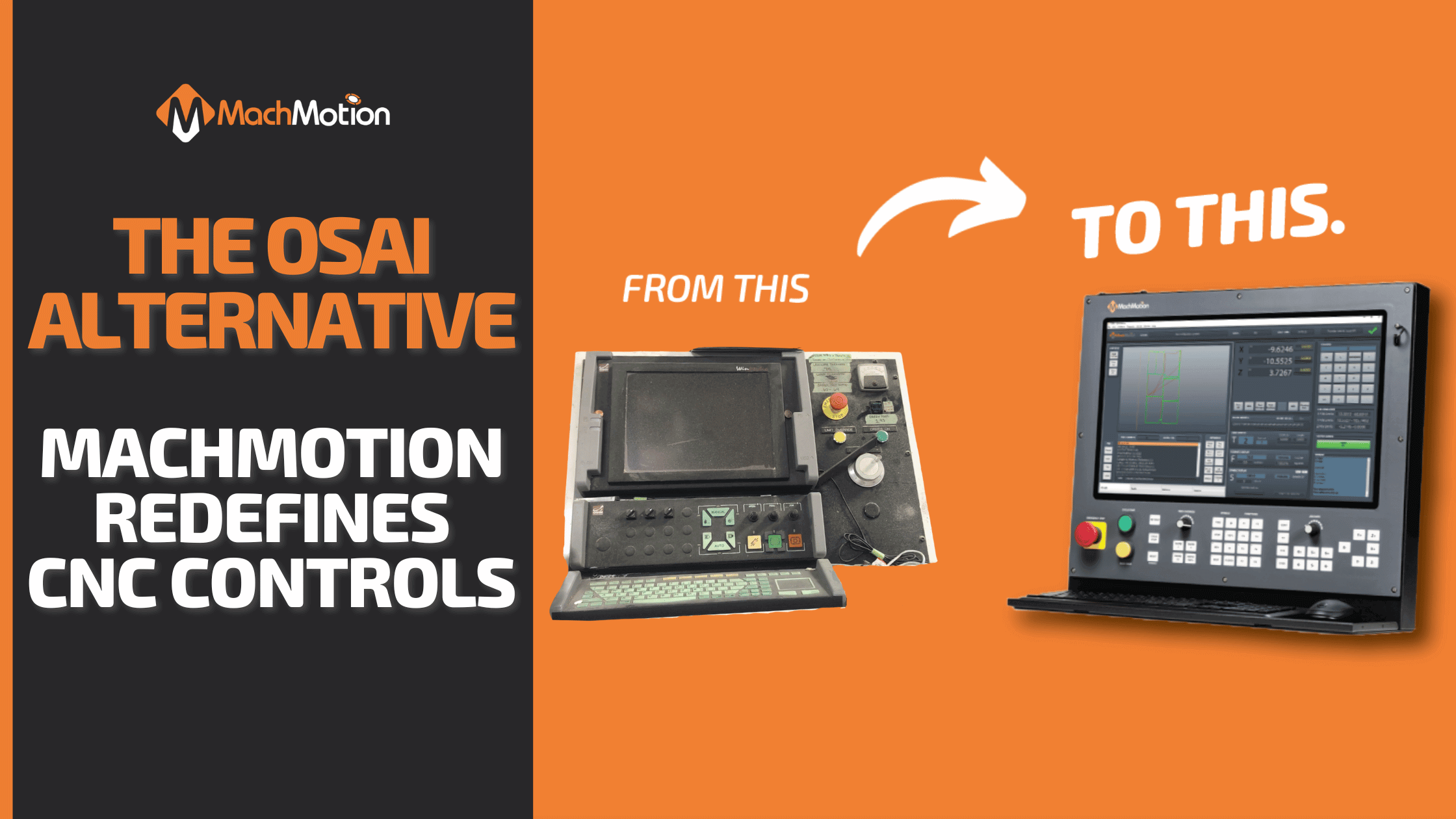

The OSAI Alternative: MachMotion Redefines CNC Machine Controls

Your CNC machines are workhorses, but they become the most problematic when their original legacy OSAI CNC controls malfunction or stop working altogether. Oftentimes, these problems manifest as control system malfunctions, the unavailability of replacement parts, outdated operating systems and software, lack of support, and difficulty onboarding new operators. The efficiency of your operations is severely impacted when these older controls start experiencing these issues and causing prolonged production downtime. Resolving problems on legacy controls demands many hours of extensive downtime and overhead costs for troubleshooting and repairs. This makes it difficult for your team to meet customer deadlines, resulting in a loss of time, revenue, and employee morale.

While we understand the frustration and struggles you may be experiencing with the CNC machines you have invested in, maintained, and rely on – it does not have to be this way. What if you could continue to utilize the machines you already own and operate them for years to come with new, fully supported controls? Though OSAI is common in the CNC industry, MachMotion delivers an alternative modern industrial controller solution designed for ease of use, equipped with remote support for the control’s entire lifespan, and redefines the future of CNC machine controller upgrades.

The Pitfalls of Legacy OSAI CNC Controls

Control System Malfunctions

It can be challenging to work with legacy OSAI CNC controls when problems arise. User-interface issues such as unresponsive buttons and darkened screens can make navigation difficult and add to your frustration. A common problem users experience during program execution is communication glitches between the CNC control and other components of the machine. Operators frequently encounter stubborn error codes that are impossible to clear. As a result, they must spend considerable time troubleshooting on internet forums and waiting for responses from their peers. System crashes become a frustrating routine, disrupting your team’s production line. In addition to all these issues, don’t forget aging components such as worn electrical wiring, circuit boards, and control panels that can result in sudden hardware failures.

Unavailability of Replacement OSAI Parts

Having to deal with older OSAI controls that are malfunctioning and need repairs or replacement parts can be a headache. During the period that your machine is still under support from the OEM, the OEM is at the mercy of OSAI’s headquarters in another country to fix the issue. It’s common for businesses to apply band-aid fixes and short term solutions just to get by another day. As these controls become obsolete, tracking down components becomes a scavenger hunt. Maintenance teams struggle with constant hunt for parts, diverting them from more proactive tasks. You can spend hours or days scouring eBay for the right components and end up facing extended downtime, waiting for critical parts that are hard to come by. Additionally, you can expect higher prices as the scarcity of rare components drives up the prices. If you are resorting to used or refurbished parts, it’s only a short-term fix with a high likelihood of failure.

Outdated Operating System and Software

Your organization may be hindered by older OASI’s antiquated operating systems that do not support networking, making collaboration difficult. In the instance they can connect to a network, they often lack appropriate network security, leaving your data and information unprotected. Trying to keep up with the latest CAD/CAM systems on outdated operating systems will lead to compatibility issues and cause massive headaches for your operators, programmers, and your IT department. In addition, post processors may face problems with older CAD/CAM software or hardware components and can lead to errors in toolpaths or tool changes. Older systems may also have insufficient memory and storage capacity, which makes running larger CNC programs difficult.

Insufficient Support

In the absence of OEM support, resolving issues with legacy OSAI controls can be very challenging and time-consuming. You’re left hanging without timely assistance and stuck relying on outdated processes and workarounds to get by. Downtime becomes your unwelcome companion, affecting productivity and promised customer deadlines. If the situation deteriorates to the point that you are unable to operate the machine at all, be prepared for expensive repair costs since you’ll need to hire external expertise or specialized technicians to tackle the issues. You may even have to ship the controller overseas for repairs, prolonging your downtime.

Difficulty Onboarding New Operators

There is a steep learning curve for older OSAI controls, making onboarding a tedious process. It can take several weeks or even months for a new operator to gain the knowledge necessary to understand and use the controls. The presence of many menus and buttons can create confusion. Operator manuals can be 100’s of pages long and don’t cover everything your team needs to know for your business’s processes. The system’s complexity increases the chances of operational errors, risking scrapped parts, rework, and other added costs. Plus, the difficulty in using the controls increases the likelihood of accidents with inexperienced operators that could have otherwise been avoided. There is a risk that your team can lose motivation when training is prolonged, causing job dissatisfaction and high turnover rates.

How MachMotion Redefines CNC Machine Controls

Highly Reliable Industrial Control Systems Made in U.S.A.

Experience a frustration-free CNC operation with a MachMotion industrial CNC controller upgrade. Our user-friendly HMI is manufactured in the U.S.A. and ensures responsive buttons and a clear, illuminated touchscreen for effortless navigation. As part of our upgrade package, we replace more than just the HMI controller – we replace the servos, motors, electrical panel, and wiring to ensure you will not experience any sudden system failures. All upgrades come with a wireless pendant that allows you to move freely around the table to manually jog the machine, cycle start/stop, feed hold, and buttons we can customize to fit your production processes. Our turn-key installation services by our team of experts is backed by our Production-Ready Guarantee. This means everything in the upgrade package has been installed correctly on the machine and that the software is configured and working according to the agreed-upon proposal, leaving you with a running machine that is ready for production. Say goodbye to the days of troubleshooting unreliable OSAI controls that came with your machine, and hello to simple, modern technology on the machines you are already familiar with.

Readily Available Replacement Parts

We eliminate the need to scour eBay for legacy CNC control parts. In order to ensure the efficiency and uptime of your equipment, MachMotion ensures that when you upgrade your CNC machine controls, you have access to readily available replacement parts for 20 years. We understand how important this is to the reliability and success of your production workflow. Having a strong service part inventory on hand at our facility allows us to swiftly deliver replacement parts to minimize downtime. You don’t have to wait for parts to ship from another country and get through customs. This allows us to help you minimize the impact of unexpected breakdowns on production schedules.

Up-to-Date Operating System and Software

Experience the freedom of MachMotion’s 2000 series modern operating system. Designed with ease-of-use in mind, our interface is intuitive and easy to operate. Conveniently connect to your network in a matter of clicks. Our controls can integrate and connect with your ERP/MRP systems to make it easy to pull up your job queue, drawings, or other documents right from the control. At MachMotion, we understand the importance of staying ahead in a rapidly evolving industry. MachMotion provides an update path and 20 year parts and service guarantee. We strive to keep your production running at optimum levels, maximizing efficiency and minimizing downtime.

U.S. Based World-Class Remote Support

We understand that occasional hiccups are bound to occur in production. Whether your CNC machines face simple or complex issues our highly trained dedicated customer support experts are just a call or click away. We provide remote support where we can remote into your control. As long as you have a MachMotion control, you will have support. In recognizing the pivotal role of customer service, we collaborate with you to address your CNC application needs in a timely manner. In addition, our online support pages are available 24/7. Here we provide a wide variety of helpful tutorials, videos, articles, and more to help keep you in production when you need it most.

Intuitive Functions for New Operators

MachMotion controls redefine the onboarding experience for new operators by offering an intuitive interface coupled with a remarkably flattened learning curve. Our controls are designed to be user-friendly, ensuring that every function is easily accessible within two clicks or less. There’s no long menus or a bunch of confusing buttons to learn. With a 21” touchscreen, full keyboard, and mouse to navigate, anyone with a few hours of training can be up and running in a matter of a few hours of training. Our commitment to intuitive design goes beyond just simplifying operations; it is a strategic approach to equalizing CNC operator knowledge. By ensuring that the learning process is accessible and user-friendly, we contribute to a more inclusive workforce, where individuals with diverse skill sets can quickly become proficient machine operators.

Conclusion

Revolutionize your CNC operation with MachMotion’s retrofit and leave behind the frustrations of obsolete OSAI controllers. Our highly reliable control systems offer a seamless upgrade, replacing not only the HMI controller but also servos, motors, electrical panels, and wiring to eliminate sudden system failures. Experience the freedom of MachMotion’s 2000 series modern operating system, designed to be intuitive and highly reliable with readily available replacement parts when needed. With an up-to-date, modern operating system and software backed by world-class remote support for the life of the control, your machine will be in production for years to come.

Considering upgrading your equipment with the MachMotion controller? We can help you and your team walk through what the process would look like for your specific machine. Contact us now at the form below or by calling us at 573-368-7399 to get started on your journey to optimizing your production!