23 Jun OSAI Controller Not Working

Is your OSAI controller not working?

Could your aging OSAI controller be causing your CNC machines to fail?

Is your OSAI controller holding back your CNC Machine?

Time after time we meet CNC owners who discover their older OSAI controller is the cause of their failing CNC machines. After as little as 10 to 15 years, these controllers can become slow, unreliable, and unsupported. Manufacturers depend heavily upon their CNC machine’s daily production for the success of their business. When the machine stops, production halts. Any unexpected downtime on a CNC machine can become very costly, very quickly. If your OSAI controller keeps stopping or you are experiencing issues with your CNC machine, read on to see what solutions are available to permanently resolve the problems with your CNC machine.

COMMON OSAI CONTROLLER PROBLEMS

OSAI Error Codes Or Faults That Can’t Be Cleared

When technology ages, from cell phones & digital electronics to CNC controllers, they tend to give us errors or faults that can’t be fixed due to the age of the devices. Typically, CNC owners look for ways to fix the problem just to keep the machine running, but are oftentimes met with difficulties. Many OSAI error codes cannot be cleared and can cause extended periods of downtime. There are no new replacements for these older types of OSAI CNC controls. If you do happen to find a used one, you will have to figure out how to install it on your own and could run into many problems. Upgrading your controller with MachMotion gives you and your team a Production-Ready Guarantee, ensuring that your machine is in working condition at the end of an installation.

Screen Stops Turning On

Machines around 10 years or older can start to experience signs of age and deterioration that can’t be fixed by a simple hardware swap. When a controller just won’t turn on, production can go down for lengthy periods of time. A few factors that play a key role in the amount of downtime experienced are time and resources spent looking for solutions, the availability of replacement parts, installation lead times, and shipping times and the list goes on. In order to ensure the stability of your manufacturing production, you should be proactive in finding a solution when experiencing unexpected shutdowns or problems turning on the control. By replacing the CNC controller and motors along with the electrical panel and other components, we can upgrade your CNC, giving you a machine you can rely on. We don’t always replace the original wiring & spindle motors but if we see damaged wiring we should replace it if possible.

No Support For Your Team

If you are operating CNC machines with older OSAI controls chances are your machine is no longer supported. If you have any issues with the control system, you will have to find a way to fix them. Whether you have the knowledge to do it on your own or have to hire a professional to come out and repair it, time and time again. With a MachMotion Control system we offer free support t for the life of the the control. Either over the phone, online or through remote support. We can even send a technician onsite if needed.

Ensure The Longevity Of Your CNC Today!

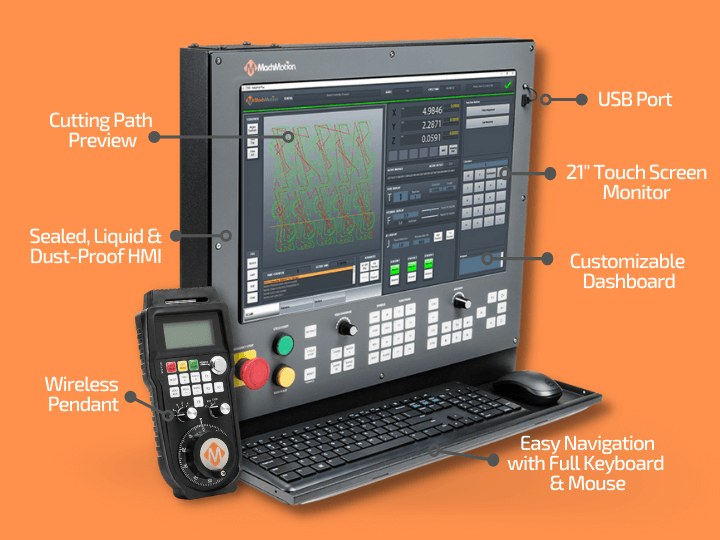

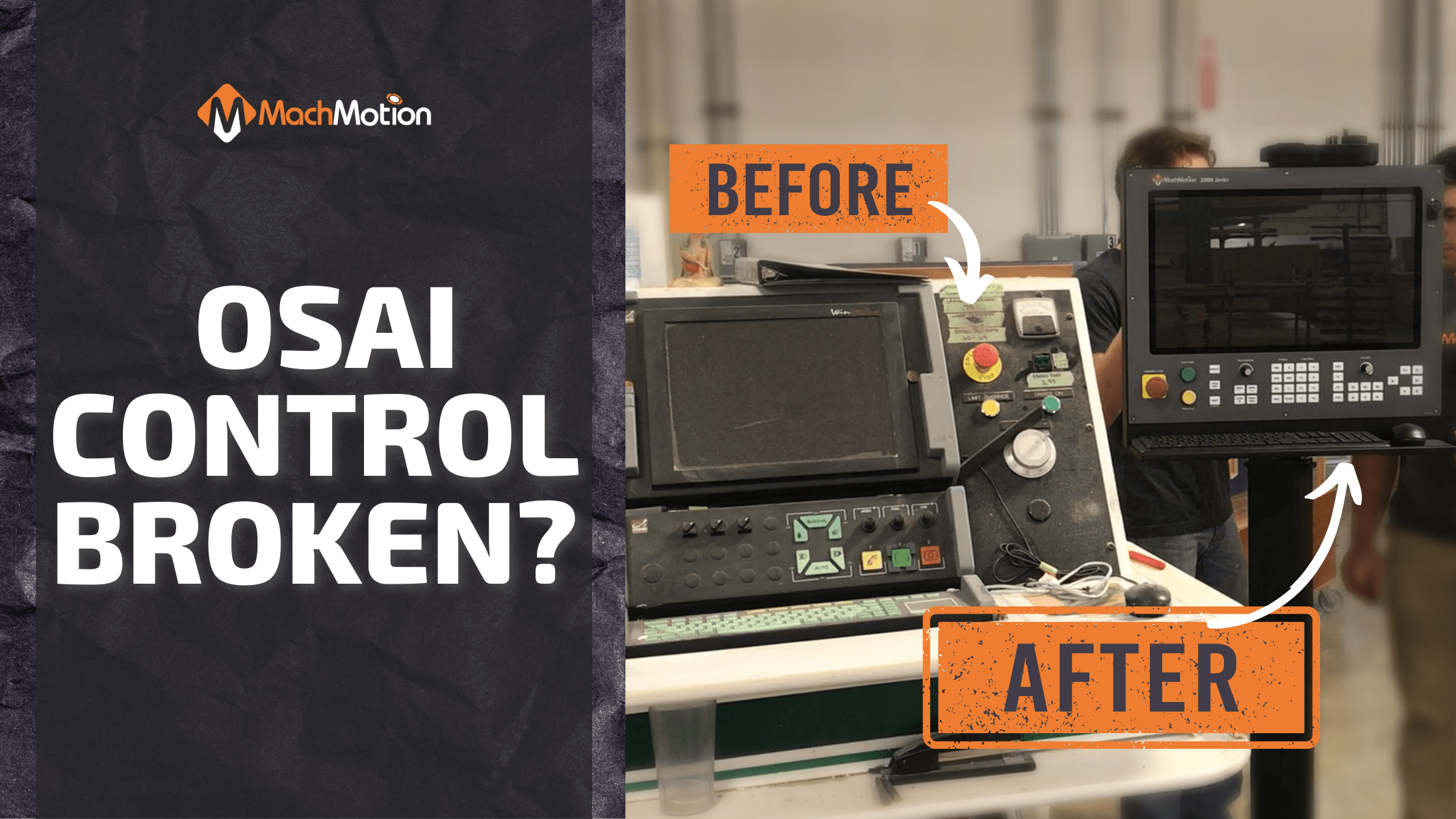

If you are operating a CNC router with older OSAI controls, you may be able to gain huge productivity improvements and greater accuracy by upgrading the CNC controls. Upgrading your OSAI controller can provide the performance you need at a fraction of the cost of a new CNC machine. Don’t replace the equipment you have when it may just need a MachMotion controller upgrade. We can help you and your team walk through what the process would look like for your machine. If you are interested in what goes into a CNC upgrade, watch the process video below! We go over the steps we took in detail when upgrading a C.R. Onsrud Panel Pro CNC router.

Our mission is to provide you with an upgrade for your CNC that will last for years to come, with unmatched remote support. If you are experiencing problems with your OSAI controller, but your machine is still running for the time being, it’s an excellent time to start planning for a CNC controller upgrade. You can make certain that your team will have a machine that is easy-to-use and more reliable than ever before. If you do run into any issues, our support team are experts in getting you back into production quickly. There’s no robots or automated services, just our experienced team, backing you every step of the way.

Connect with one of our CNC retrofit experts today to see how you can upgrade your CNC machine!