18 Aug OMAX Waterjet Retrofits and Repairs

OMAX Waterjet Retrofits and Repairs: Controller Issues That Could Be Costing Your Productivity

Have you been encountering OMAX waterjet error codes you cannot clear? Are you experiencing a malfunction with your display screen? Is your controller overheating? Find out how you can maintain the productivity of your waterjet cutter.

While OMAX waterjet cutting machines are high-quality, the cost of repairs can add up quickly if you aren’t careful. What happens when unexpected problems occur with your OMAX waterjet? Old or outdated components can make your watejet less productive and in some cases even dangerous to work with. Costly and frequent repairs are detrimental to production and cause unnecessary stress to machine operators. This can be incredibly frustrating because depending on the issue, it could mean frequent repair time. Owners and team leads have to come together to discuss the options they have to ultimately make a choice on what to do to proceed efficiently. There are some choices that come to mind when it comes to an older waterjet that is in need of new controls.

Older OMAX Waterjets: Options for Solutions

- Do Nothing

The first option is to do nothing. You can just let the machine sit and wait for repairs or just take it out of commission altogether. This won’t result in a working machine, but it is an option.

- Perform Repairs As Needed

Another option is to perform band-aid repairs as the machine breaks down. As long as there are parts available and you can afford unplanned downtime, repairs are an option. Replace a board here or an enclosure fan there, and you’re diminishing your maintenance budget far before the end of the year. See what your waterjet repairs may be costing you here.

- Replace With A New Waterjet

Next option is to source a new machine, whether that be brand new or used, but that might take months to get a unit shipped and installed at your facility. You also have to consider the logistics of moving the current machine out and a new one in, which may mean moving more than just the waterjet itself. There are also costs associated with scrapping the old waterjet and replumbing a new one, which may be harder to do with the existing infrastructure and the size of the machine.

- Upgrade Your Controller With A Retrofit

Lastly, you may want to consider upgrading the machine you already have with a new controller, motors, wires, and electrical enclosure. By choosing this option, you can keep your existing OMAX waterjet for a fraction of the cost of buying a new system. With minimal disruption, frustration, and downtime this is a great option to get your OMAX waterjet back in production. Scroll down to see what questions our customers have had about MachMotion waterjet upgrades and how this may benefit you!

OMAX Waterjet Retrofits FAQs

If an upgraded controller sounds like the right fit for your OMAX waterjet, read on to learn more about what goes into a MachMotion controller retrofit.

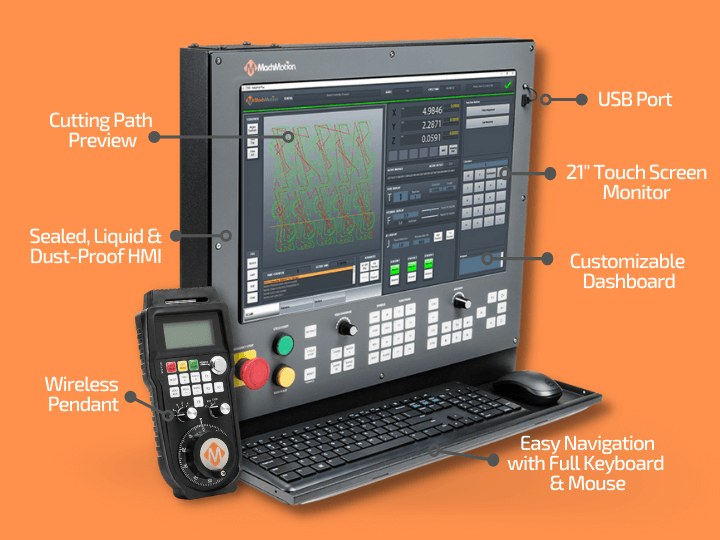

When I upgrade my OMAX waterjet, what does it come with?

WATERJET UPGRADE PACKAGE INCLUDES:

• 21″ touch-screen CNC waterjet controller

• Customizable User Interface

• Wireless pendant

• Pre-wired & labeled electrical panel

• Yaskawa servo drives & motors

• 1-Year Warranty

• Lifetime Remote Support

Can I install it on my own? What are my installation options?

Yes! With basic mechanical and electrical skills your team can install this kit yourself. We can work with your capabilities and do part of the install, if you don’t feel comfortable with some parts. We also offer professional turn-key installation. All you have to do is point us to your machine and our expert installers will take care of the rest!

What if I run into a problem while doing a self-installation?

Our highly-trained support team is here to help you every step of the way. When you call in for assistance, you speak to a real person every time. No automated systems or robots. We support more than 1,500 companies globally—like Ford, DuPont, and NASA from our facility across the globe. Once the controller is installed, we remotely assist you for the lifetime of the controller.

Can I use my existing Nesting software?

Yes! The MachMotion 2000 series controller can integrate with your existing nesting programs. Compatible CAD/CAM programs include SigmaNest, AutoDesk TruNest, Hypertherm ProNest Nesting Software, Nest&Cut Nesting Software and many more! If you are unsure, contact us to see if your software is compatible.

What if I’m unsure of the mechanical condition of my OMAX waterjet?

We offer machine inspections to verify the condition of ball screws and backlash, linear guideways, lube system, etc. Any mechanical issues discovered during a health inspection should be handled prior to upgrading the controls. This will not only maximize the waterjet’s performance, but it will also upgrade your operator’s controller experience. We’ve partnered with professional machine rebuilders to make these repairs easily as part of our process.

How long does it take to train an operator?

It only takes about an hour to train an operator, you can have your operators up and running very quickly! The MachMotion 2000 series control is an intuitive, user-friendly touch screen with a full keyboard and mouse. With customizable buttons, you can set repetitive operations to run in a single click. It’s really that simple!

Can I test out the controller before purchasing an upgrade?

Absolutely. We can ship you and your team a demo controller and schedule an interactive presentation to show you how the controller works. This gives your team the opportunity to engage with the user interface and see if it’s a good fit for your OMAX waterjet and operators.

Upgrade Your OMAX Waterjet To The Industry Standard

Ultimately if you have an OMAX waterjet cutter that is running with an aging controller and is almost out of warranty or the warranty expired recently, it’s a great time to consider a CNC controller retrofit. When you opt to upgrade, you get to keep the machine you’re already familiar with and enjoy all the same technology as a new machine. Saving labor, reducing downtime, and ultimately saving yourself headaches when your waterjet machine stops working is what you’re looking at when you invest in a waterjet retrofit. Upgrade your control system today with our complete retrofit kit, shipped and ready to install. If you need to hold onto your cash for now, there are Financing options available through our partner Ascentium Capital, a subsidiary of Regions Bank.

Learn more about our CNC waterjet controller upgrades here.

BELOW ARE SOME OF THE OMAX WATERJET CUTTER MODELS THAT WOULD BE GOOD CANDIDATES FOR A MACHMOTION CNC CONTROLLER UPGRADE:

OMAX 80X

OMAX 80X-1

OMAX 80X-2

OMAX 120X

OMAX 120X-1

OMAX 120X-2

OMAX 120X-3

OMAX 160X

OMAX 160X-1

OMAX 160X-2

OMAX 160X-3

OMAX 2626

OMAX 2626xp

OMAX 2652

OMAX 5555

OMAX 55100

OMAX 60120

OMAX 80160

OMAX GlobalMAX 1508

OMAX GlobalMAX 1530

OMAX GlobalMAX 2040

OMAX Maxiem 1530

OMAX Maxiem 2030

OMAX Maxiem 2040