14 Jun FADAL 4020 VMC LASER ADDITIVE/SUBTRACTIVE MACHINE RETROFIT

FADAL 4020 VMC LASER ADDITIVE/SUBTRACTIVE MACHINE RETROFIT

Fadal 4020 VMC Laser Additive Control Retrofit

This customer came to us for a hybrid additive/subtractive manufacturing solution.

Project Overview:

This customer came to us like very many do. With a unique need and no idea how to approach it. They had a proven process for additive manufacturing with powdered metals and wanted to integrate it on an industrial machining center to allow for hybrid additive/subtractive manufacturing.

Customer Need:

- Integration to up to 48 powder feeder devices (PLCs controlling material metering)

- Onscreen camera feed for part alignment and laser process monitoring

- Integration to IPG fiber laser\

- Onboard custom path generation wizard for part repair

MachMotion Solution:

MachMotion built a wizard for a teach and learn repair that allowed the user to create the G-Code for additive repair by simply jogging the machine around the area to be repaired.

With the open architecture of our development platform we were able to integrate the camera feed into the screen design. This allowed the user to set fixture offsets using the on screen camera feed.

MachMotion built macros that were imbedded in the G-Code that defined the powder feeds and laser intensity but then also built a tab on the screen with full control of laser power and all powder feeders during cut to allow the user to modify the process during the additive build.

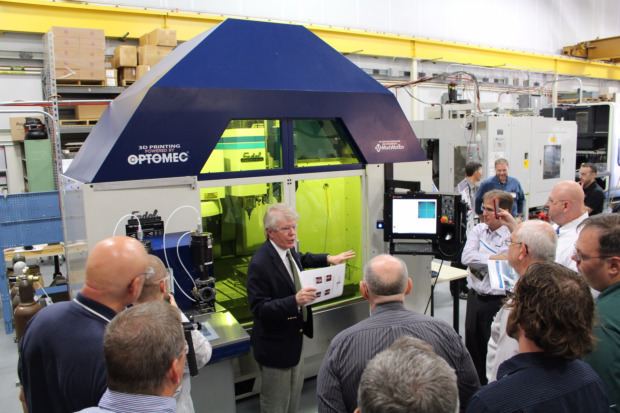

Both retrofitted Fadal 4020 w/ Laser Additive

Fadal 4020 with 4th/5th Axis Trunnion Table

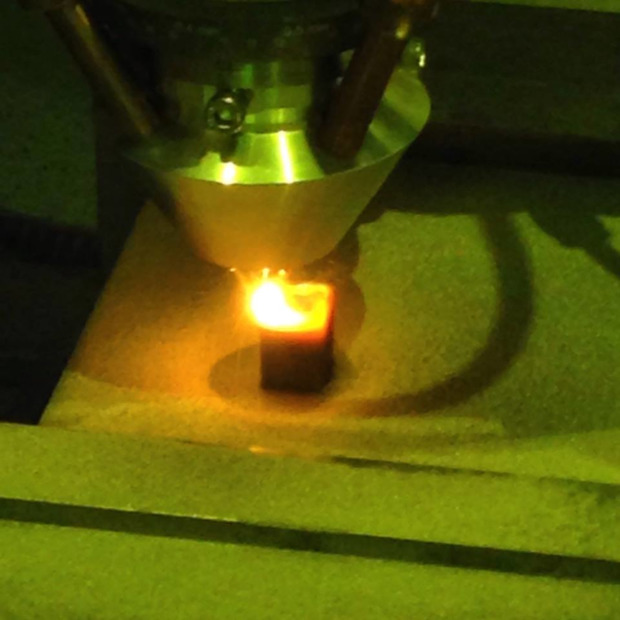

Laser Additive In Action

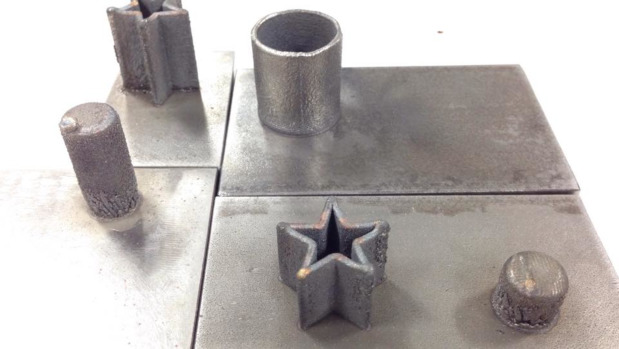

Printed Test Shapes