07 Oct CUSTOM GRINDING SOLUTION FOR MIAMI-BASED AIRCRAFT ENGINE REPAIR GROUP

CUSTOM GRINDING SOLUTION FOR MIAMI-BASED AIRCRAFT ENGINE REPAIR GROUP

A Miami-based precision aircraft engine repair center was looking to grind a large-diameter part with precision. On their existing control system, setup took quite some time and it was exceptionally difficult to measure the amount of material that needed to be removed during each cycle. Without documentation or the support of the control’s manufacturer, they sought out other options.

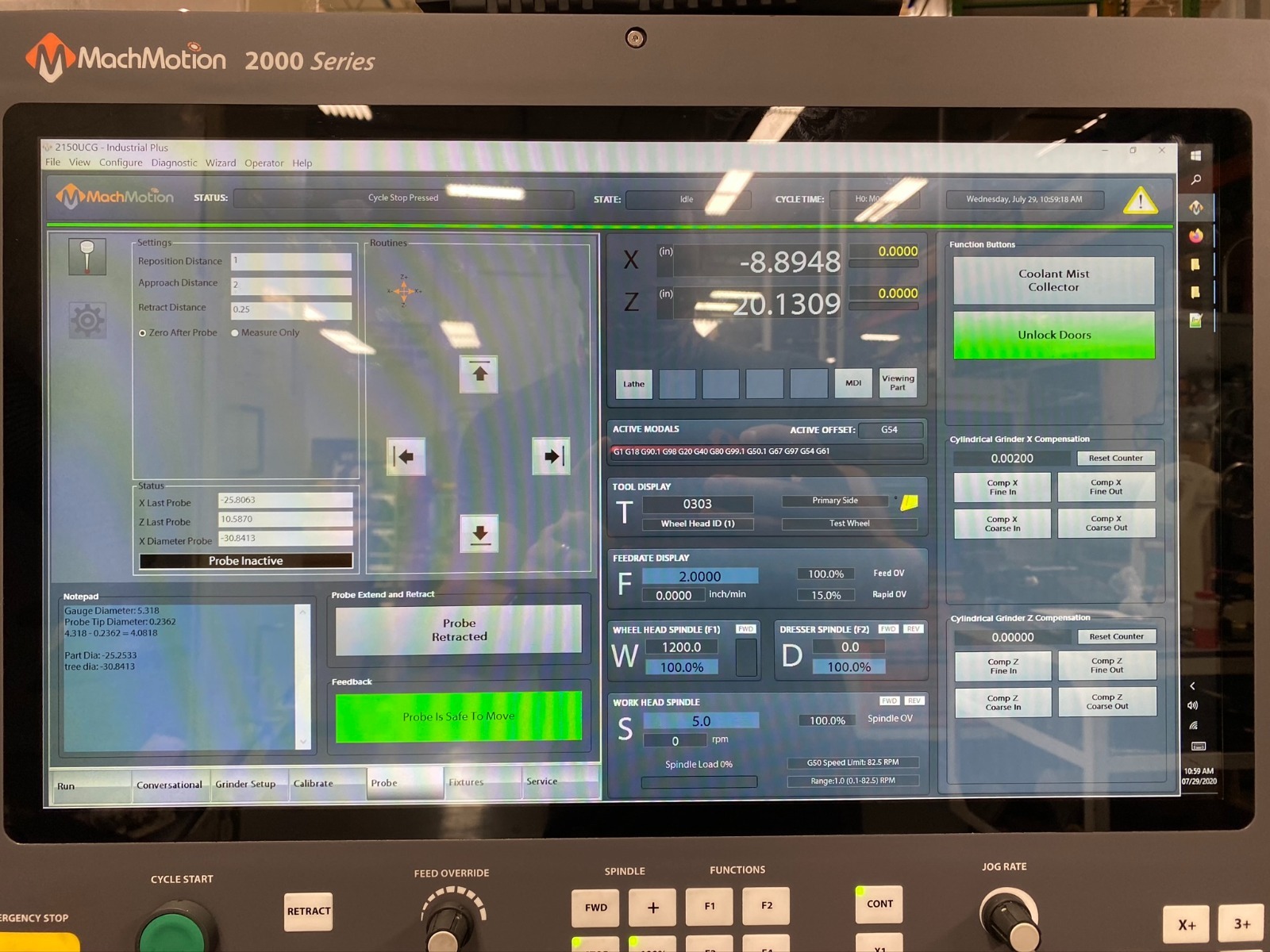

When they reached out to MachMotion and explained their needs to our sales engineers, the company decided that a Renishaw precision arm and probe, set up with integration to a custom grinding cycle, would best solve their problem. MachMotion then created grinding cycles to meet their specific needs and built a custom page for their probing, making setup as easy as possible.

Working together, we were able to retain the existing machine’s original turning abilities and add custom grinding. The aircraft engine repair center can use the standard conversational cycles for turning on a VTL, then switch to custom grinding with an integrated probe system, easy setup, and dimensional testing.