01 Apr Is A Turnkey Retrofit Right For Your CNC Machine?

Is A Turnkey CNC Retrofit Right For Your Machine?

In this blog we will help guide you through questions that can help you and your team answer the ultimate question: Is a turnkey retrofit right for your CNC machine? Read on to find out!

What should I consider when upgrading my existing CNC machinery?

We understand that considering a turnkey CNC retrofit for your machine can be an intimidating and confusing undertaking. Understanding why a machine may or may not be a candidate for a turnkey CNC retrofit can be the most important thing to consider when making your decision. To make this step easier, we’ve prepared a quick blog to help you! In this post, we’ll answer some of your most commonly asked questions about CNC retrofits and expand on the differences between a turnkey CNC retrofit and a DIY retrofit. Read on to learn more!

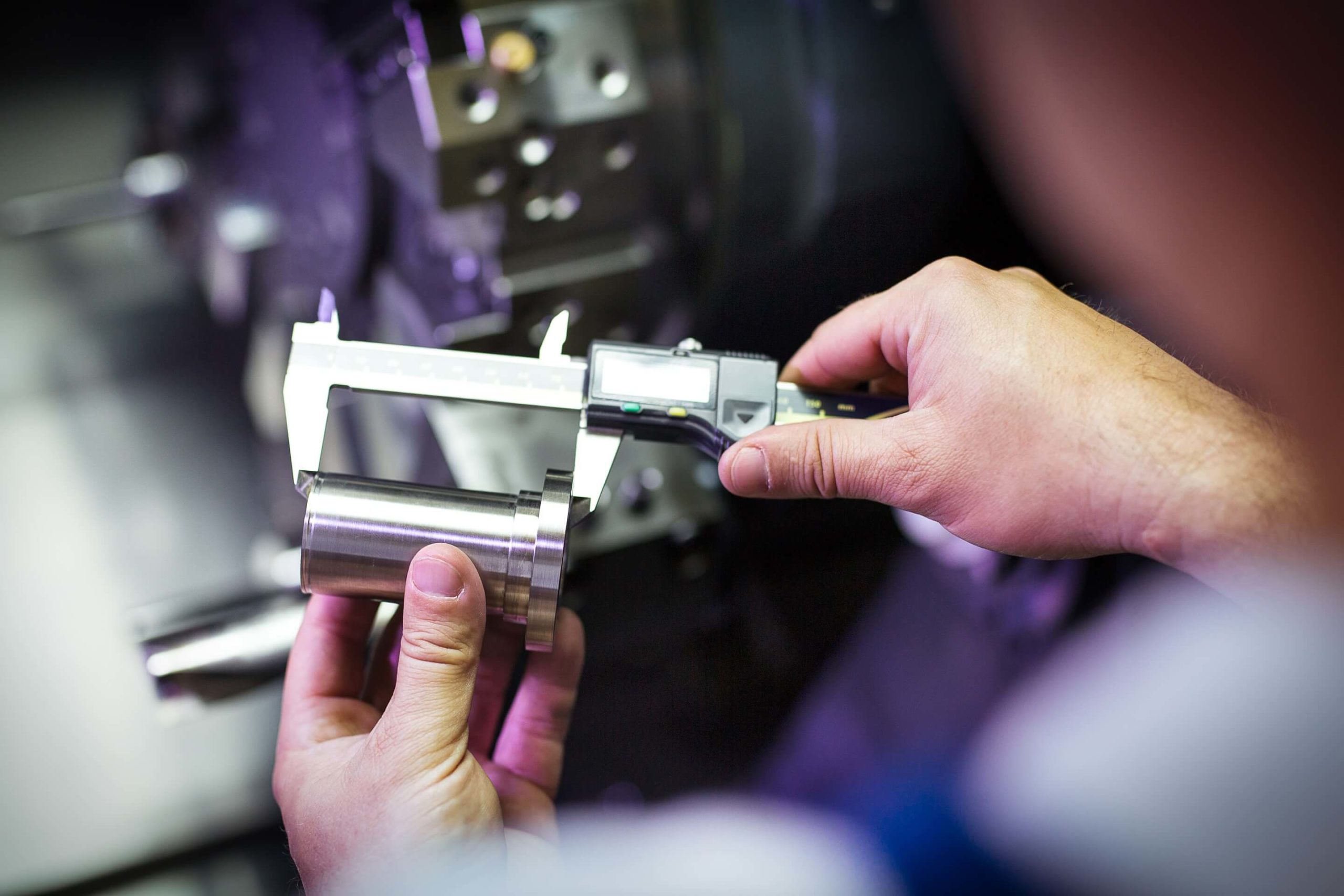

Is my CNC making quality parts?

One of the first things to consider when looking into a CNC retrofit is if your machine is currently running and making quality parts?

In the event, your machine is not mechanically running properly or not making quality parts, a turnkey CNC retrofit won’t be the first step to getting your equipment back in working order. A CNC machine rebuild can update mechanical hardware that has worn out over the years. Once it is rebuilt and mechanically sound, then you can look at a CNC controller retrofit for your machine!

If your machine is running and making quality parts, but experiencing frequent breakdowns or is no longer supported by the OEM, your machine may be a good candidate for a turnkey CNC retrofit. Turnkey CNC retrofits are a cost-effective way to extend the life expectancy and production capabilities of your CNC machinery when the mechanical hardware is functioning properly.

How large is the machine?

If you are planning a turnkey CNC retrofit, the size of your machine plays an important role. Considering the costs of both buying a new high-end CNC machine and moving an old bulky one, a turnkey CNC retrofit can decrease the overall spend on your budget. Commonly we see large legacy boring mills, waterjets, and cnc routers that have good iron but could use a controller upgrade.

If the machine is simple enough (like a knee mill or 3-axis CNC router), we can provide a fully integrated control package that you can install yourself. Our technical support team can walk you through the motor mounting and wiring. We can log in remotely into the control for the full software setup. But, on the more complex machines, we recommend just buying new. A full turnkey install and integration of the new control will come close to what a new machine costs! This brings us to our next question…

Is it economical to replace my existing machine with a brand new one?

For many CNC machine shops, it just doesn’t make financial sense to purchase new machines. Instead, for a fraction of the cost, they retrofit their existing machines with new technologies that can help them stand out against their competitors and increase the production of their shop dramatically. In many cases, a turnkey CNC retrofit is more affordable than purchasing a brand new machine and it’s a much more efficient way to keep your existing machinery. Not only do turnkey CNC retrofits lower your initial capital expenses, but they are also quite a bit cheaper to operate.

Turnkey CNC retrofits start to make sense at one-third of the cost of buying a new machine – This is a good rule of thumb when weighing your options. Other things to think about when considering buying a brand new CNC machine are:

- What are the lead times for delivery?

- What does support and customer service look like?

- Do I need to replace all my fixturing and tooling?

- What are the rigging costs for moving the machines?

- Does this affect any other departments?

Has it become difficult to find machine service and support?

There’s a great deal of value in investing in turnkey CNC retrofits for unsupported equipment. Oftentimes, businesses find themselves with legacy CNC machinery that is no longer supported by the OEM. This can be difficult if you find your machine down and no way quick way to get help. Retrofitting an older piece of machinery can be the perfect solution for companies that need basic support for their machines.

We are very familiar with common problems & interruptions that come with owning CNC equipment. MachMotion’s Turnkey CNC Retrofits and DIY Self-Install packages include FREE Remote Technical Support for the lifetime of your machine. This includes email, phone, and remote login support for all of your troubleshooting needs. We are always available to help with setup, answering questions, and more!

What are some of the key benefits of a Turnkey CNC Retrofit with MachMotion?

If you’re passionate about making things, chances are your relationship with your CNC machine goes beyond simply running parts. In all likelihood, you dream about the projects you could create if you had a more capable machine. From reducing unplanned downtime to improving performance and precision, we’ve written a couple of articles about the Key Benefits of CNC Waterjet Retrofit as well as the Key Benefits of CNC Router Retrofits. Click the links to read the blogs.

What is the difference between a Turnkey CNC Retrofit and a DIY Self-Install Kit?

Turnkey CNC Retrofit

CNC retrofits can be tricky. That’s why our Turnkey CNC Retrofit is all-inclusive. This includes installation by our experienced install team and hands-on training post-install. At MachMotion, our team has performed 1000’s of installs over the years on all types of CNC machines. Our Turnkey CNC Retrofit includes a new HMI Smart Controller, New Electrical Panel or Cabinet, Servo, and Motors for your CNC Machine. Depending on the type of machine, we replace components as needed. Our installers will come out and take out the old controller and components and install the new ones. After the install, we will train your team and go over the basics of your new controller so everyone is speaking the same language! We uphold the MachMotion Production-Ready Guarantee, meaning that when we leave you at the end of an install, your machine will be production-ready and in working order.

DIY Self-Install Kits

MachMotion offers DIY Self-Install Kits for an affordable alternative to a turnkey CNC Retrofit. With basic electrical skills and minimal mechanical design and fabrication, you can install this CNC Retrofit Kit all on your own. The same functionality as a turnkey retrofit, except you install it yourself. Our knowledgeable support team is available to assist you with any questions you may have during the installation process. Our goal was to provide a complete controller upgrade kit that would allow business owners to minimize the installation expense associated with professional turnkey installs.

I’m still unsure. Should I consult with a CNC Retrofit expert before finalizing my decision?

Yes! MachMotion can walk you through what a retrofit would look like for your machine type, providing peace of mind when it comes to making your final decision. Adding a turnkey CNC retrofit to your machining center will have a significant impact on both your productivity and quality. With the right provider, turnkey CNC retrofits can offer a host of benefits including increased machine capabilities, increased flexibility, and enhanced safety. Before you begin looking for a turnkey retrofit provider, however, it is important to talk with a CNC Retrofit Expert to help you understand your best options. While the versatility of these retrofits make them a great option to improve many different CNC machines, some may have better options to consider than retrofitting. Regardless of whether your machine is a candidate or not, we hope you found the information presented in this guide helpful.