25 Apr From Frustration to Success: How American Gear Company Overcame Their KOMO VR 512 CNC Router Problems

From Frustration to Success: How American Gear Company Overcame Their KOMO VR 512 CNC Router Problems

Plagued With Problems

American Gear Company’s KOMO VR 512 CNC router had been plaguing them with problems. Abrupt downtime and missed deadlines were becoming a regular occurrence for their operators. Their highly skilled craftsmen were not only frustrated, but discouraged by this as well. The company, which specializes in hand-crafted outdoor gear such as surf and skateboards, was faced with a difficult decision: either purchase a brand new CNC router or attempt to patch up their existing KOMO 4-spindle gang CNC router with what we like to call “Band-Aids and bubble gum.” With this solution, they would have to find parts for their machine to fix it up, which was not a guarantee that something else would not break in the future.

A New Discovery

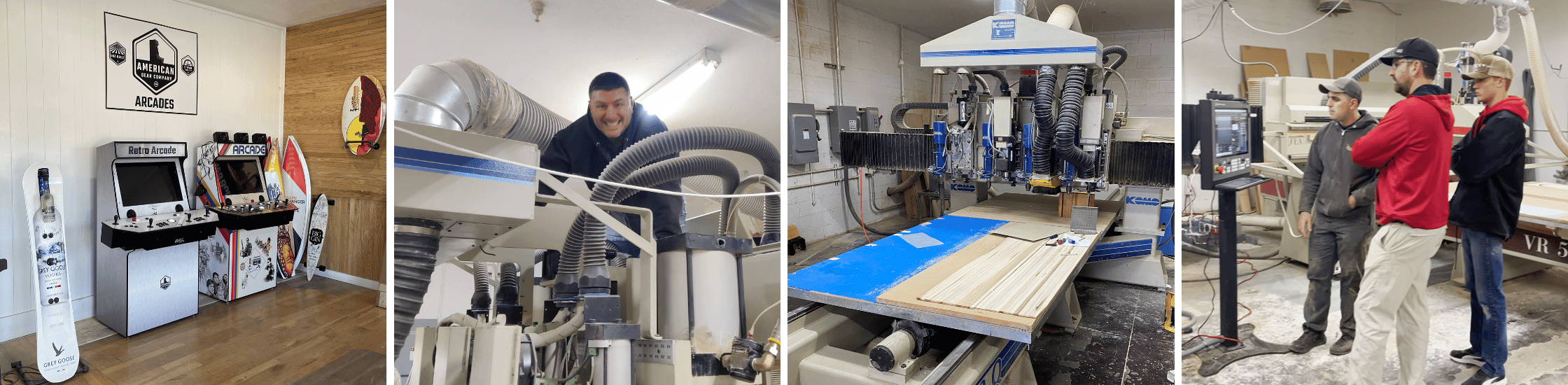

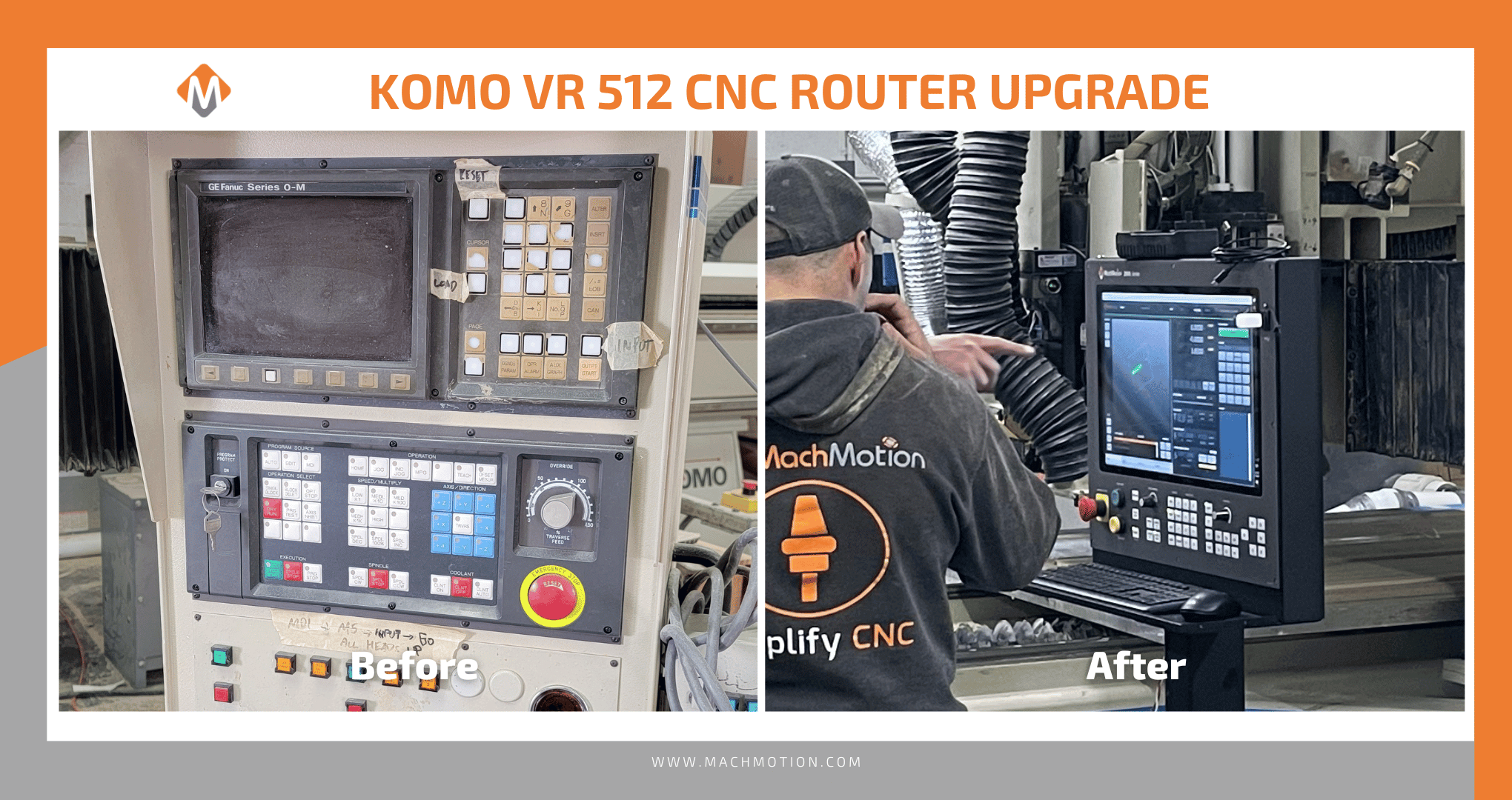

Ryan, the owner of American Gear Company, knew that something had to be done quickly to keep his business moving forward. That’s when he discovered MachMotion. He learned that retrofitting his existing machine was a reliable and cost-effective long-term solution for companies like his. This would mean his machine would be equipped with a new HMI controller, motors, wiring, and electrical panel, as well as the addition of a wireless pendant. He could get the results they needed from their existing machines for a fraction of the price of buying a whole new machine. Ryan’s team wouldn’t have to go through the hassle of disposing of their KOMO CNC router, a sturdy machine despite its control issues.

KOMO VR 512 CNC Router Optimization

Optimizing their KOMO VR 512 CNC router with MachMotion’s expert installation team was the best decision for American Gear Company. They were able to add new capabilities to their existing router, including automatic tool changers and a tool setter, enabling them to produce surf and snowboards more efficiently and with less downtime. MachMotion’s expertise in retrofitting CNC machines provided them with a customized solution that fit their specific needs.

A Sigh Of Relief

As the installation progressed, the tension began to ease, and a sense of relief swept through the company. The company was overjoyed to see their router back up and running, with newfound capabilities that they never thought were possible. By retrofitting their CNC router, they were able to save thousands of dollars in costs associated with purchasing a new machine, including new spoiler boards, rewriting programs, new tooling, and rigging to name a few. They were able to continue using their KOMO VR 512 CNC router and avoided the downtime associated with lead times and moving a new machine into their facility.

Back Into Production

With a seamless transition that integrated into their production environment without the need for creating new Gcode programs, they were back in production in one week. MachMotion’s expert installation team was able to enhance their CNC router’s performance and keep up with the demands of their growing business. By retrofitting their machine with new controls, they were able to improve their KOMO VR 512 CNC router’s capabilities, resulting in increased efficiency and productivity. They were able to avoid the downtime and costs associated with purchasing a brand-new CNC router.

Can you relate?

You’re not alone. If this story seems all too familiar, consider retrofitting your CNC router with MachMotion & see the benefits for yourself. Contact us at 573-368-7399 or fill out the form below and we’d be happy to discuss your options with you!