15 May Customer Success Story: Mastercraft Boats KOMO Machinery Upgrade

Breathing New Life into KOMO Machinery: Mastercraft’s CNC Router Retrofit Success Story

Mastercraft Boats is famous for their top-of-the-line boats that are known for their quality construction, innovative designs, and cutting-edge technology. Behind the scenes at their manufacturing facility in Vonore, Tennessee, their production operations began experiencing frustrations with their old FANUC control on their 2001 KOMO VR 508 CNC router in their replacement upholstery department. After purchasing two brand new KOMO CNC Routers for their production department, the hindrances of the old control on the older KOMO machinery became apparent and began to cause inconveniences that extended beyond the machine operator.

Mastercraft’s 2001 KOMO Machinery Issues

Mastercraft’s CNC router’s performance began declining over time. Although the core of the KOMO machinery was built to last a lifetime, the current control was aged beyond repair. As a cornerstone of their replacement upholstery production process, this caused problems that were unavoidable when operating the machine. The lights on buttons flickered or wouldn’t work at all, the screen dimmed intermittently, and navigating the controls became a frustrating endeavor. With two newer KOMO routers equipped with 24-slot tool changers, the 8-slot tool changer on their older KOMO became an anomaly and posed a logistical nightmare. With the difference in tool changers, the machine required separate programs to properly cut and disrupted their workflow efficiency. The CNC router’s declining performance threatened to jeopardize production timelines and compromise the quality standards Mastercraft prides itself on.

Upgrading KOMO Machinery Controls With MachMotion

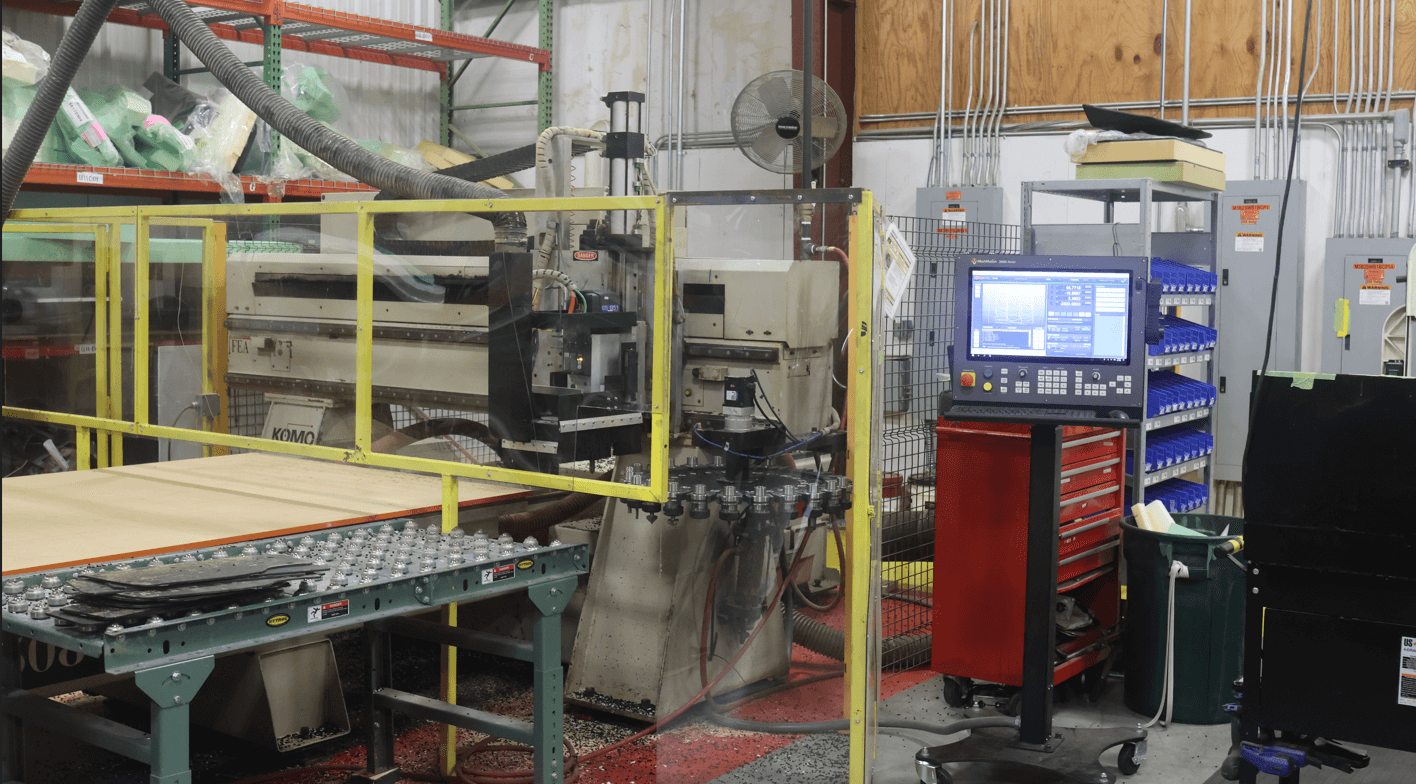

Instead of replacing their existing CNC router, they wanted to figure out a way that they could keep the machine. Not only did they already have all the tooling for this machine, but it was in a location of their facility that would make moving it out and replacing it with another machine a long and difficult process. They also needed this machine to keep their replacement upholstery department up and running. Recognizing the potential to extend the life of their KOMO VR 508 CNC router, they reached out to MachMotion. With decades of expertise and innovative solutions, the idea to update the controls and breathe new life into Mastercraft’s trusted CNC router was now within reach. With a vision for long-term preservation and future growth, Mastercraft embraced the opportunity to modernize their machinery. MachMotion’s team orchestrated a comprehensive turnkey upgrade. This included replacing the outdated FANUC control system, old spindle, motors, electrical panel, wiring, and seamlessly integrated a new 24-pocket carousel tool changer, along with a new tool setter to help expand their capabilities and increase efficiency. Through meticulous installation and cutting-edge technology, the CNC retrofit not only restored functionality but also unlocked untapped potential, paving the way for enhanced productivity and streamlined processes. Mastercraft not only preserved their investment but also set the stage for future growth and development.

Optimizing CNCs With MachMotion Upgrade Solutions

With their new CNC control and components installed, their KOMO VR 508 CNC router was ready to get back into production. Whether MasterCraft is using one of their new KOMO routers with the standard Fanuc or their upgraded KOMO running MachMotion control, they now can use the same G-code files on all their routers, with one post-processor, streamlining their process over their network. This journey of Mastercraft serves as an example of how to navigate the dynamic landscape of manufacturing through upgrading existing machinery. By collaborating with MachMotion, they overcame their challenges with their old control and their production emerged stronger than ever. As machine technologies advance, Mastercraft’s story reminds us that with vision, determination, and the right partners by your side, anything is possible.

To learn more about how you can upgrade your CNC machine, click this link to visit our upgrades page.