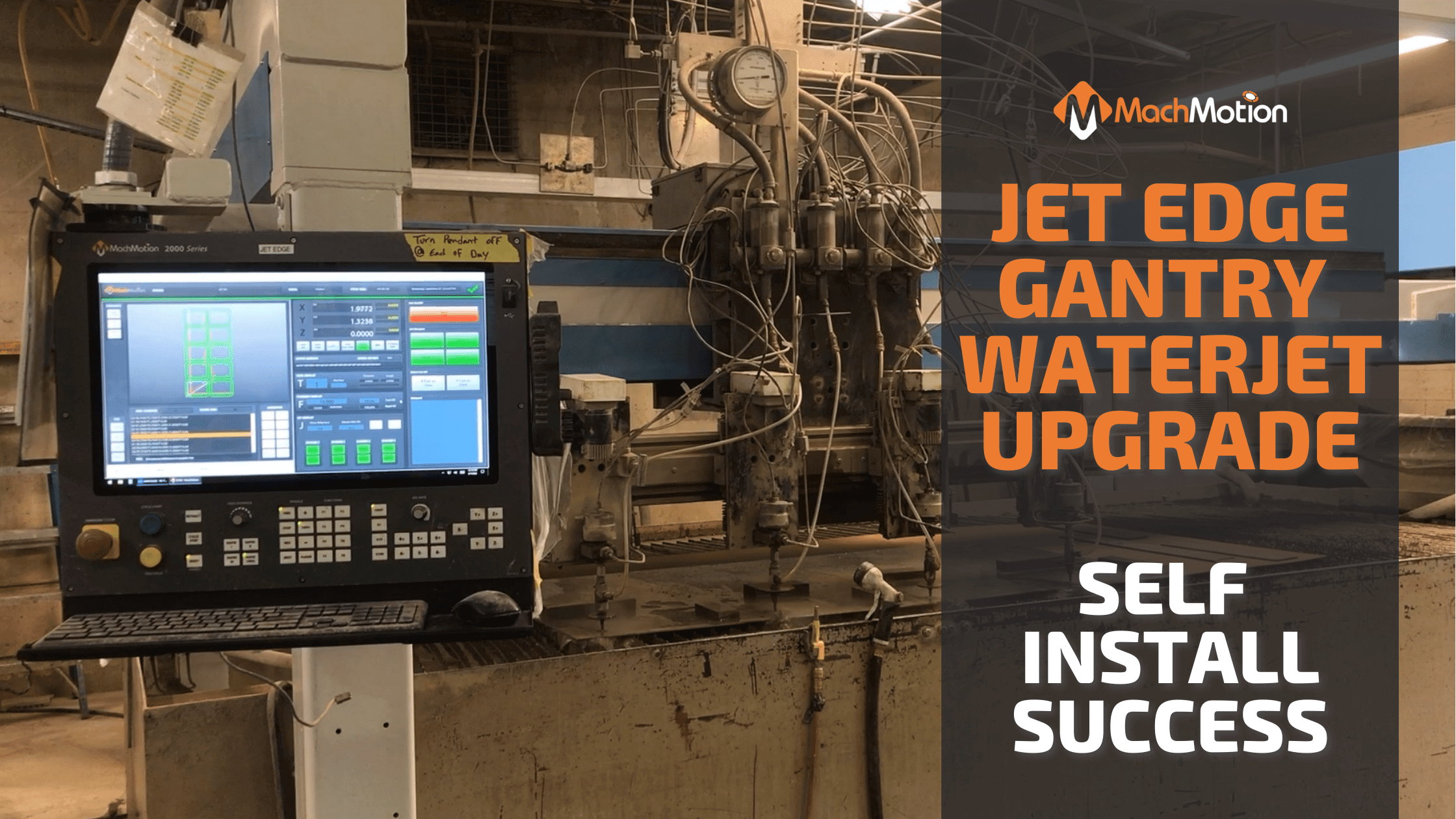

04 Oct Customer Story: Jet Edge Waterjet Self-Install Controller Upgrade

Customer Story: Jet Edge Waterjet Self-Install Controller Upgrade

Industry-Leading Manufacturing Company

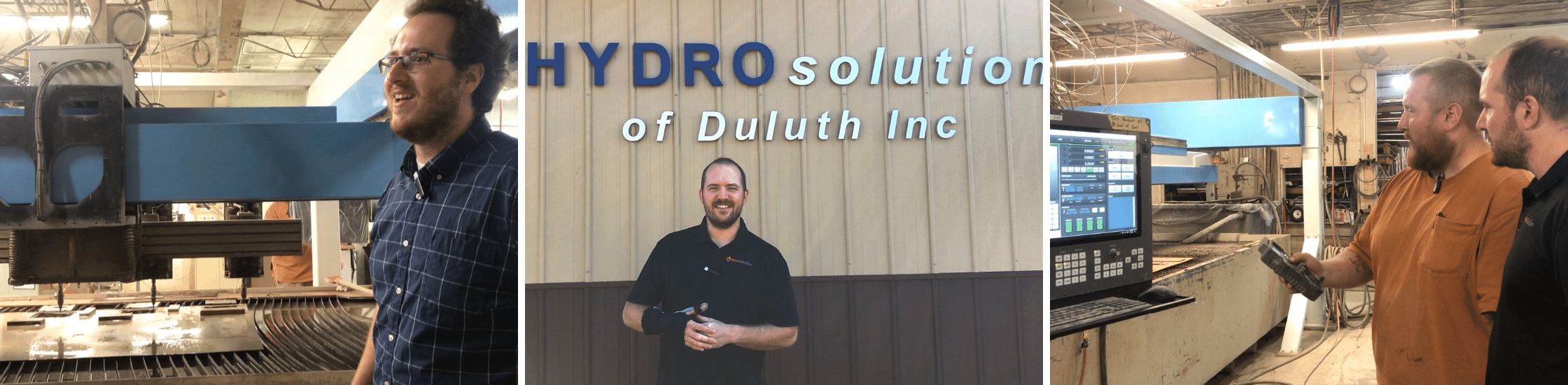

In the wake of unexpected downtime on their main Jet Edge waterjet cutter, HydroSolutions of Duluth knew they had to decide how to keep production going and deliver customer parts on time. The Jet Edge waterjet was their workhorse, utilized for heavy-duty high volume applications. HydroSolutions is an expert manufacturing company that specializes in waterjet cutting, metal forming, CNC machining, and product assembly. They work with industries such as aerospace, medical, architecture, and others to support their needs. As a result of their innovative processes and conformance to ISO 9001:2008 + AS9100C quality standards, they remain competitive in the industry and ahead of the competition.

An Imminent Problem Identified

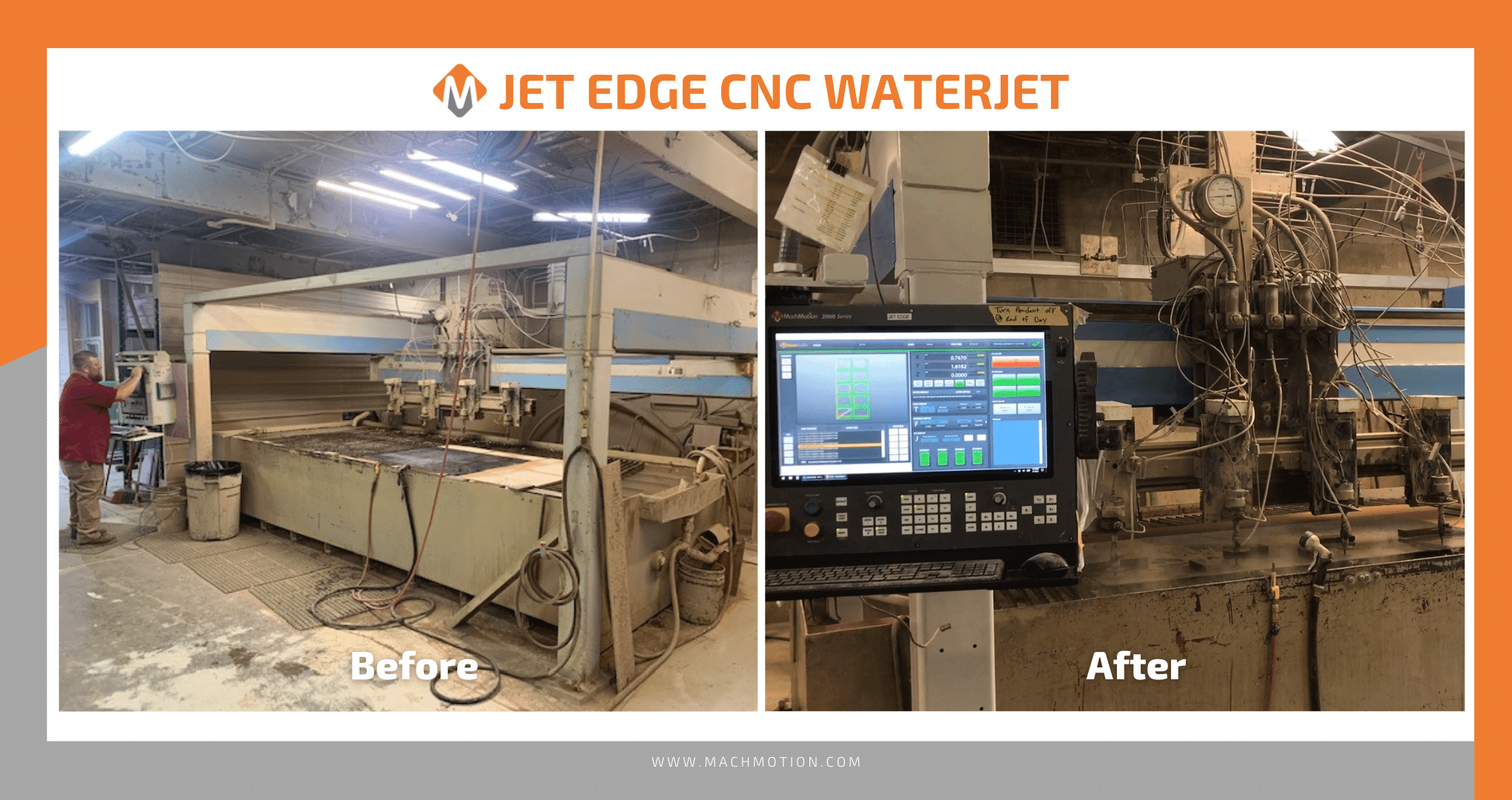

The iron on their Jet Edge waterjet cutter was good. The control system was wearing down from a mechanical aspect with the ballscrews being worn out. They were also suffering from electrical failures as well. When drive faults and problems with the control was brought to the attention of the owner of HydroSolutions, he wasted no time identifying what his options were for solutions. He felt very confident that if it was mechanical, it was something he could fix. Although, when it came to the electrical side with a controller involved, he knew he had to seek out a solution from a reputable source. The biggest factor was that the obsolete software and controller had begun to hinder their production on their main waterjet.

As a long-term customer of Jet Edge Waterjet Cutter Motion Systems, the owner reached out to Jet Edge. He discovered that the OEM no longer supported the control or software. Unfortunately, their solution that was available on the market was not compliant with HydroSolution’s current cyber security requirements to be compliant with NIST 800 171. He started looking for solutions by asking his connections for assistance in the matter. When a company down in the Twin Cities, that sells aftermarket waterjet parts, had recommended he take a look at MachMotion’s waterjet controller solutions, he reached out to our sales engineers.

Discovering A Customized Controller Solution

HydroSolution’s machine is a very unique Jet Edge waterjet cutter. This gantry model has one Z-axis with 4 cutting jets that allow them to cut multiple parts at the same time. “We have been told over and over by countless people that have come in, both competitive and non-competitive with this product that we have up there, that don’t ever trade the machine because you’re not going to get as good of one. And today they’ll still tell you that,” said the owner. They were well aware that this Jet Edge waterjet would not be easily replaced. Upgrading the controls to reclaim the waterjet and give it a second life was the best resolution to keep them in production.

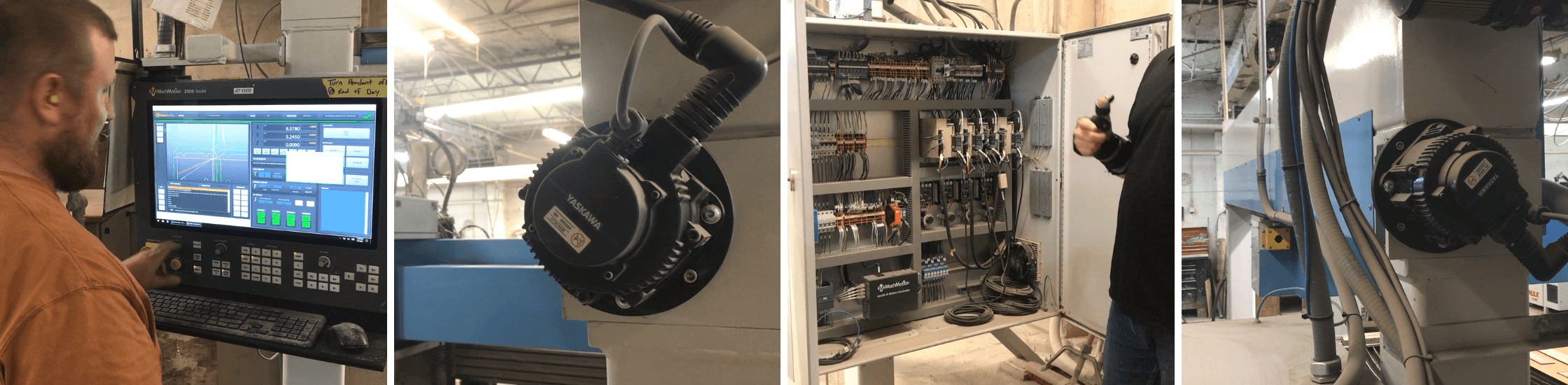

After reaching out to MachMotion for a solution to their JetEdge controller dilemma, HydroSolutions was able to talk through their applications, concerns, and vision they had for updating their waterjet. It was identified during a demonstration that it was identified that adding a servo motor to the Z-axis would be very beneficial to their application and production needs. The addition of the servo to the Z-axis would allow their machine to pierce accurately while cutting and move upward to ensure that the tips wouldn’t drag or crash. This wasn’t something they had even considered before discovering this was possible in the demo. Since their team was good with mechanics, they decided to move forward with a self-install of the MachMotion 2000 series CNC control system upgrade on their JetEdge waterjet.

Self-Installation Success

After the all-inclusive upgrade package for the Jet Edge waterjet was decided on, engineered, and fabricated, it was time to get to work. All components were tested by our quality control team before shipping out. One of MachMotion’s rebuilder partners helped to do a complete replacement of the ballscrew. The other mechanical components were completed by the Hydrosolutions team. The installation was well within their wheelhouse house and went very smoothly. Their team also installed the CNC controller upgrade package which included mounting the front-end HMI controller, the electrical enclosure, and all new servo motors and drives.

MachMotion came out after to commission the machine and train their operators. Due to their conformance requirements, they also had to have this machine calibrated by laser mapping. In order to carry out the calibration in a timely manner, we were able to connect them with one of our calibration partners to complete the task. The whole process took about a week with their team beginning the installation process on Saturday, getting motion by Tuesday, and calibrating & cutting parts by end of the day Thursday. Dan Larson, the owner of HydroSolutions stated in our interview that “remarkably that was exactly the schedule we had planned for and doesn’t happen in the real world very often.” By Friday of that week, they were ready to get back into production!

The MachMotion Jet Edge Waterjet Controller Solution

When you choose to upgrade, you get to keep the machine you have. Saving on repairs and reducing downtime when your waterjet cutter stops working are excellent reasons to invest in updating your controls. With our complete retrofit package, you’ll be able to upgrade your control system on your own with a self-install like HydroSolutions, or hire our expert team to do it for you. At MachMotion, we provide a long-term supported solution for obsolete CNC controllers and software.

The 2000 Series CNC Controller runs on a PC. It comes with a touch-screen, full keyboard, and mouse, helping to reduce the need to go back to a desktop computer to make program changes. Each CNC Controller upgrade comes with a wireless pendant that you can control the machine with, enabling operators to move freely. It even works with your existing design software, integrating with your existing files to jump back into production quickly. The system also comes with onboard diagnostics that alert the operator of any problems during cutting. You can customize the interface for your operations in seconds. When you choose MachMotion, you get more than just a retrofit. It’s an upgrade!

Learn more about our controller solutions for waterjet cutters here!