19 Mar Uncovering Hidden Value In Your Aging CNC Machines

Overlooked And Undervalued: Uncovering Hidden Value In Your Aging CNC Machines

Understand the operational resilience of your CNC machines and what components still thrive beyond control system failures.

Are you struggling with aging CNC machines that seem to be holding on by a thread, solely due to their outdated controls? If you own or operate CNC machines purchased more than a decade ago, you’ve likely encountered issues with outdated controls. It’s a common difficulty faced by many CNC manufacturers. What if we told you that beneath those aging controls lies an abundance of hidden value waiting to be unlocked? The core components of your machines including the iron-strong base, well-serviced spindle motors, mechanical framework, and tooling compatibility offer significant future potential. By upgrading your machines with a CNC controller retrofit you can double the life of your existing machine and harness the hidden value that lies within. Throughout this blog, we’ll explore the often overlooked yet valuable components of aging CNC machines, and reveal how MachMotion’s controller upgrade solutions can unlock their full potential.

The Hidden Value In Aging CNC Machines

Your aging CNC machines hold untapped potential, housing components that have proven their durability over time and remain in excellent condition with regular routine maintenance. The solid iron-strong base, robust mechanics, and well-preserved components present a wealth of opportunities for revitalization and enhanced productivity. Let’s delve into how you can leverage the enduring quality of these machines with a CNC controller retrofit to unlock their full potential and drive your manufacturing operations forward.

Iron-Strong Base

The foundation of any CNC machine is its iron-strong base. While other components like the electronics and controls, may show signs of wear and tear over time, the base remains dependable and reliable. Its stability and rigidity contribute significantly to the overall durability and performance of the machine as a whole, making it a valuable asset that should not be underestimated. As manufacturers seek to optimize their production processes and enhance productivity, recognizing and leveraging the value of the base is essential for achieving long-term success. Upgrading controls allows you to keep the iron-strong base without having to invest in a brand new one that will serve the same purpose.

Serviced Motors

Motors are the powerhouse behind the functionality of your CNC machine. When well maintained with regular servicing and maintenance, these motors can last a long time, offering extended durability and reliability, even after controls start to fail. With consistent upkeep of your motors, you’re not just making them last longer but also protecting your entire CNC system investment. Replacing the controls of an aging CNC machine with good motors can unlock numerous benefits, including improved performance, compatibility, and long-term reliability.

Mechanical Framework

Beyond the surface of aging CNC machines is a resilient mechanical framework that stands the test of time. Components such as guideways, ball screws, spindles, and other vital parts may still be in excellent condition despite the machine’s age. Rather than undertaking the expense of replacing these components outright, upgrading the control system offers a practical and efficient solution to extend the lifespan and enhance the performance of aging CNC machines.

Tooling Compatibility

One of the most considerable challenges of replacing an aging CNC machine is the compatibility of existing tooling. Cutting tools, fixtures, and other accessories are often designed to fit the specifications of a particular machine. Replacing the entire machine could make these tools that you’ve invested in obsolete. This leads to additional costs and logistical challenges if you are trying to replace the whole machine. By upgrading the controller while retaining the core machine components you can ensure seamless compatibility with existing tooling. This allows you to maximize efficiency and minimize disruption on your production floor.

Unlocking The Full Potential of Your Aging CNC Machines

Assessing Your CNC Machine’s Condition

We understand the dilemma and stresses caused by aging CNC machines. The question of whether to invest in a new machine or leverage the potential of your existing one isn’t always easy. With our expertise in breathing new life into aging CNC machines by upgrading the controls, we can help you evaluate the current condition of your machines with our Machine Health Check service. We come onsite and do a full inspection of the mechanical and electrical components of your machines. Upon reviewing your machine’s essential components, and evaluating any mechanical issues, we can help you decide if it is time for you to optimize the machines to their full potential.

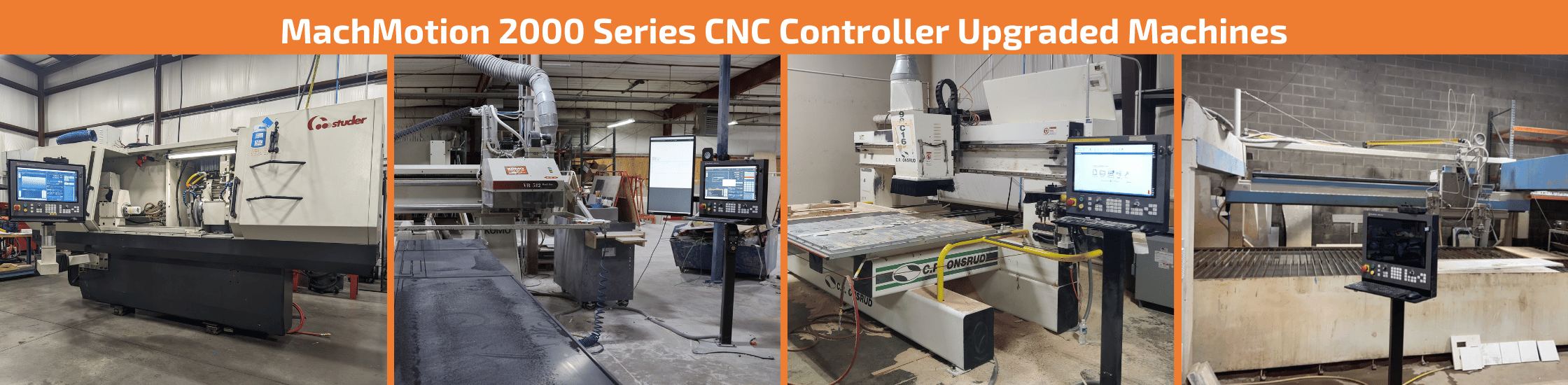

Harnessing the Power of Your Existing CNC Machines

At MachMotion, we offer a long-term solution that extends the life of your aging CNC machines: CNC controller upgrades. With our extensive experience in revitalizing thousands of CNC machines over two decades, we provide cost-effective solutions tailored to your machine’s specific needs. By upgrading the controls system, we utilize the hidden value in the iron-strong base, well maintained motors, mechanical framework and tooling within your equipment. As part of our upgrade package, we replace more than just the HMI controller – we replace the servos, motors, electrical panel, and wiring to ensure you will not experience any sudden system failures.

Conclusion

As you navigate the challenges posed by outdated controls, it’s crucial to recognize the hidden value within your equipment. By leveraging the undeniable quality of the iron-strong base, well-maintained motors, mechanical framework, and tooling compatibility, you can unlock their full potential and drive your manufacturing operations forward. At MachMotion, we understand the importance of maximizing the investment in your current CNC machines.

Our controller upgrade solutions offer a cost-effective pathway to revitalizing aging equipment, ensuring it continues to operate efficiently, doubling the life of your machine. Contact us to schedule a Machine Health Check and explore how we can help you optimize your equipment for maximum performance and longevity. Your CNC machines hold the potential for continued success – let us help you unleash it. Contact us now at the form below or by calling us at 573-368-7399 to get started on your journey to extending the life of your CNC machines!