24 Aug Customer Story: Optimizing A Cylindrical Rubber Roll Grinder

Customer Success Story: Optimizing Rol-Tec’s Cylindrical Rubber Roll Grinder With A MachMotion Retrofit

A Major Production Setback

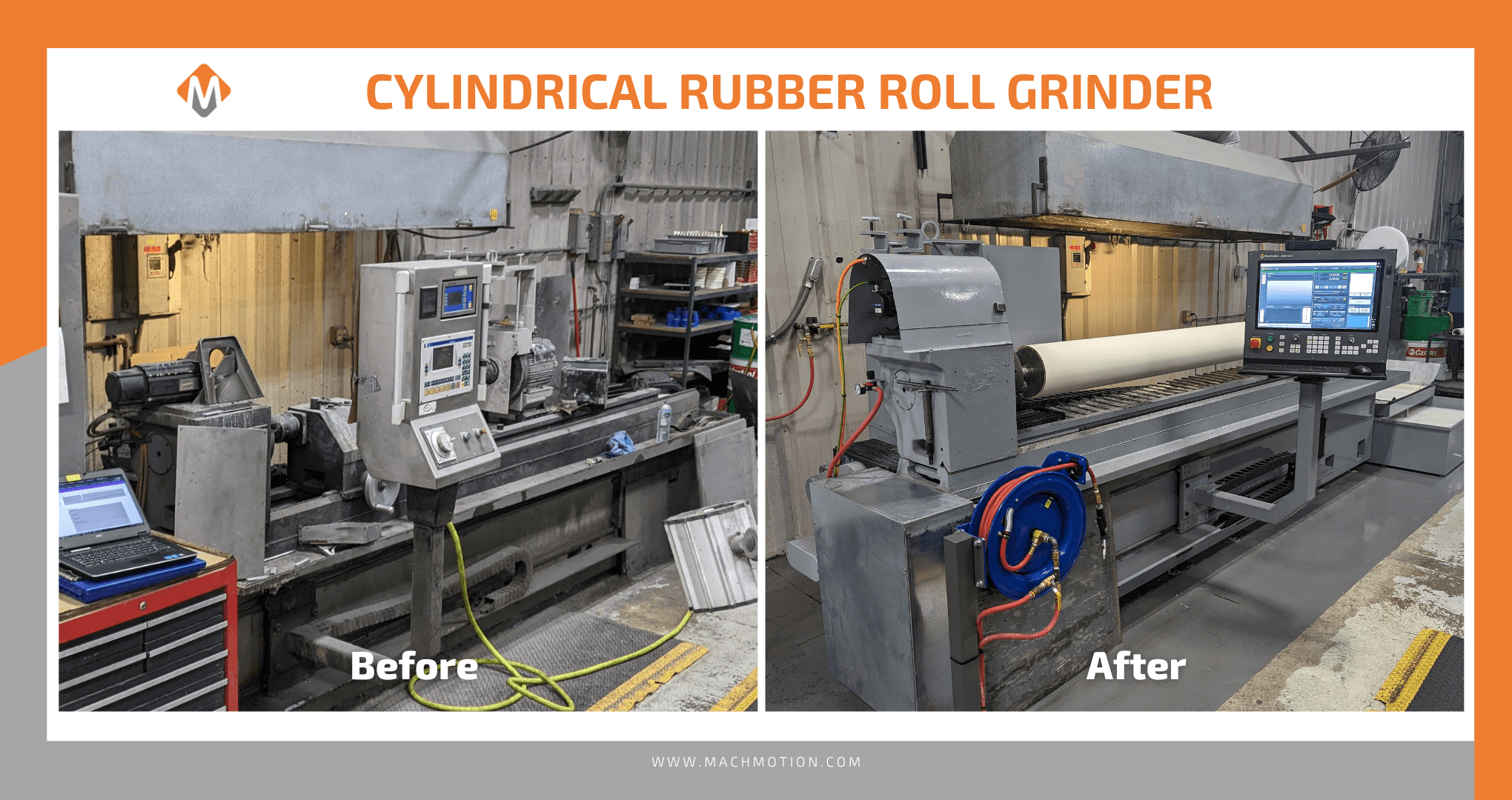

Rol-Tec, a leading provider of precision manufacturing, faced a significant operational setback. Their cylindrical grinder, a crucial asset in their rubber roll production, failed due to a crippling control malfunction. This unexpected halt caused major disruptions in their production lines, forcing them to assess the machine’s condition and viability.

The challenge that Rol-Tec confronted was worsened by the age of their cylindrical grinder. As technology advanced, equipment that was once cutting-edge no longer met the needs of the industry. The problem was made very apparent in the obsolete controls that no longer met the demands of modern precision manufacturing. Struggling under the weight of obsolescence, their rubber roll grinder was teetering on the precipice of abandonment.

Seeking A CNC Retrofit Solution

The once-thriving machine now stood idle, and Rol-Tec knew they had to do something quick to keep them in production. Rol-Tec found a glimmer of hope with a solution to resurrect their rubber roll grinder. They reached out to MachMotion and began their journey to giving their machine a second life. The journey toward revival commenced as the machine was retrofitted with state-of-the-art controls to replace the antiquated ones.

A New Life For The Cylindrical Rubber Roll Grinder

As the machine came to life with its new controls, it once again became a powerful production asset for the company. Beyond the tangible benefits of the retrofit, the process of training operators was streamlined, thanks to the intuitive and user-friendly interface of the upgraded controls. Efficiency and competence improved as the learning curve flattened, ensuring that the transition was smooth and quick.

Back In Production

Rol-Tec’s decision to implement a MachMotion retrofit has proven to be a strategic decision. The rejuvenation of their rubber roll grinder was not just a revival of machinery, but a demonstration of the adaptability and durability of these well-built machines. The rubber roll grinder, which was once considered obsolescence, is now supported and can be run for years to come. Learn more about CNC retrofit solutions for your CNC machines!