25 Mar CINCINNATI CENTERLESS GRINDER 325-12 CONTROL RETROFIT

CINCINNATI CENTERLESS GRINDER 325-12 CONTROL RETROFIT

Cincinnati Centerless Grinder 325-12 Control Retrofit

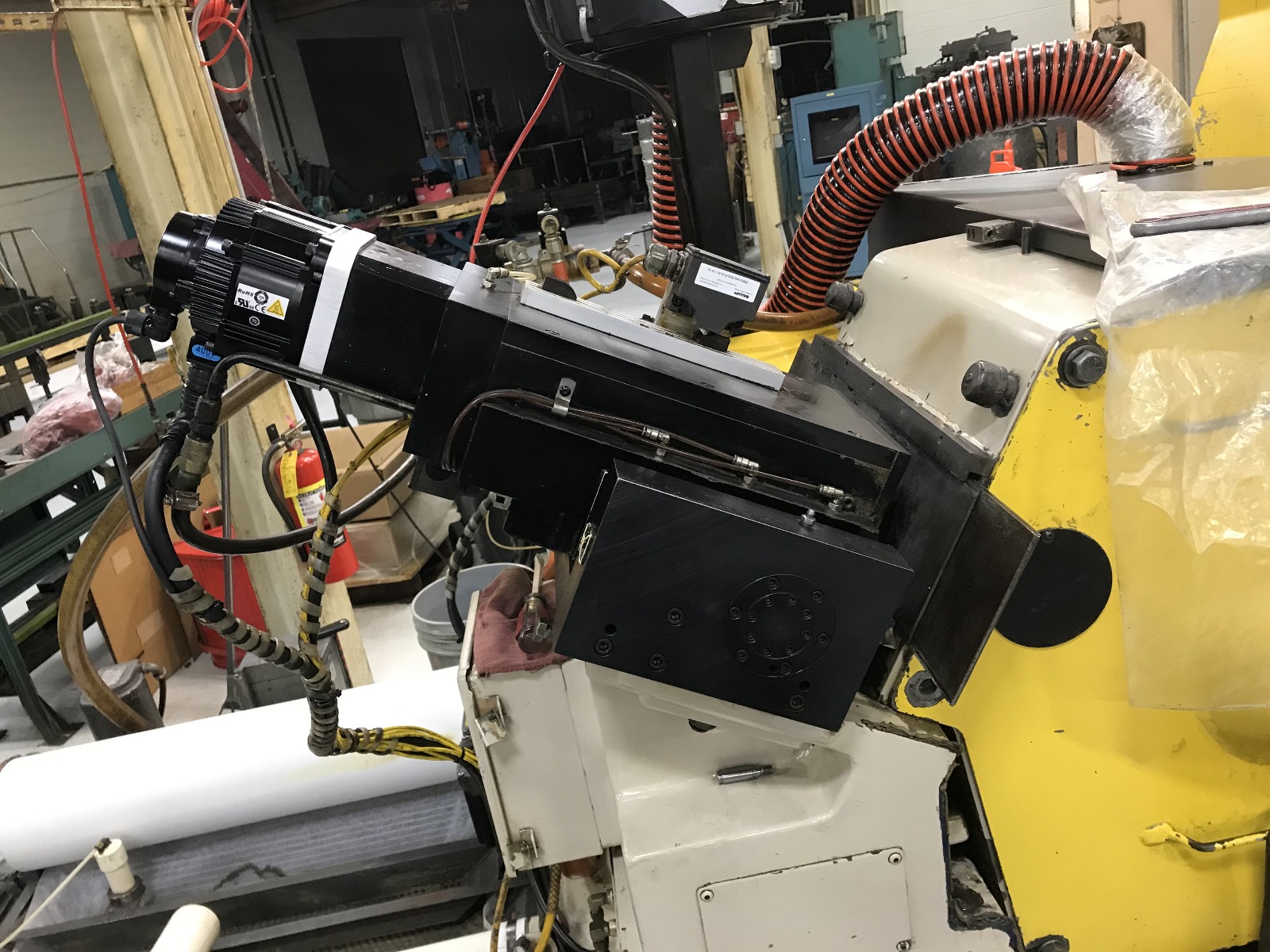

Minnesota Grinding has a Cincinnati 325-12 centerless grinder that had been retrofitted by CRI with their EZ-Touch control, an Allen Bradley 1394 PLC control and 1326 series servo motors, over twenty years ago. The Allen Bradley PLC control was malfunctioning, and both support and repair parts were no longer available. The original retrofit company could no longer support the outdated technology. Minnesota Grinding needed to retrofit the Cincinnati 325-12 centerless grinder once again.

A New Control Package

Minnesota Grinding researched to find the best company to retrofit their centerless grinder, but everyone they contacted offered way more than was needed, increasing the cost. Minnesota Grinding found that MachMotion was economical without sacrificing quality and had superior support, top of the line parts, and was dependable. Minnesota Grinding had the opportunity to meet MachMotion at IMTS 2018 and was impressed with their knowledge and attitude.

MachMotion offered a 3 axis control retrofit solution that included:

• 1 axis infeed with Yaskawa servo motor

• 2 axis grind wheel dresser with Yaskawa servo motors

• New grind wheel and reg wheel VFDs for speed control

• New 21″ touch screen control and pre-wired electrical panel

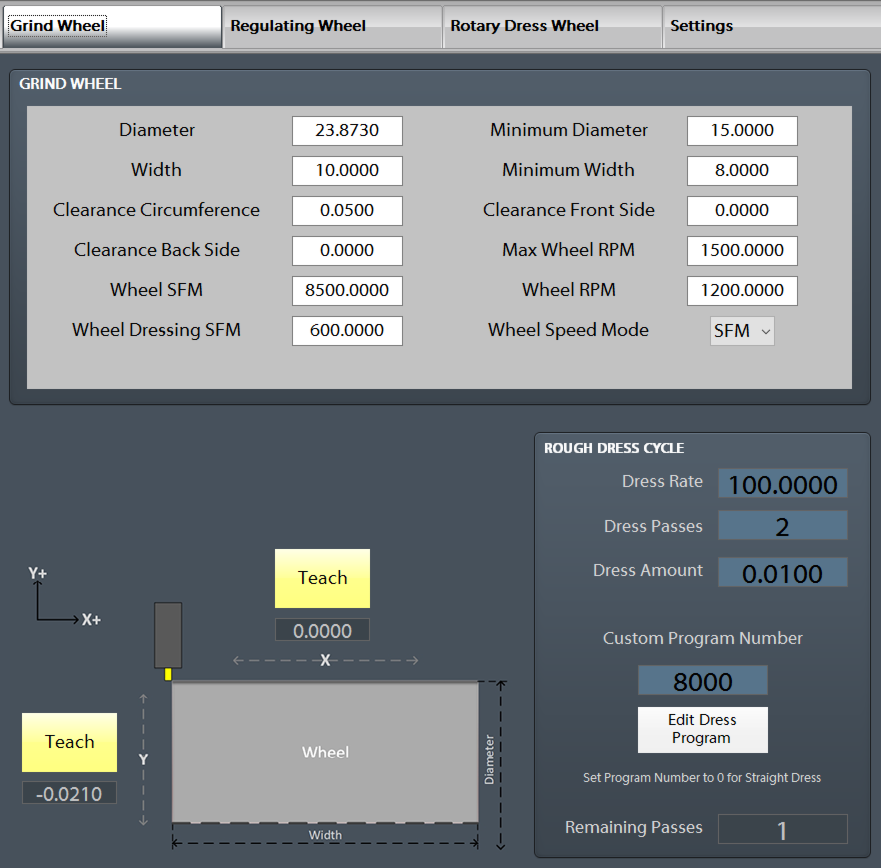

With a MachMotion CNC control, the 2 axis dresser is easily programmed with coordinated motion allowing the operator to dress any shape in the grind wheel.

Turnkey Grinder Control Retrofit

MachMotion offers complete turnkey control retrofits. For the Cincinnati 325-12 centerless grinder, MachMotion completed the entire retrofit process. MachMotion arrived at Minnesota Grinding within two weeks after receiving the PO to remove the old control system and was back on site five weeks later with the new control system to start the retrofit. “I was very impressed with MachMotion, every deadline they set they met, and everything they said they were going to do, they did,” said Harlen Gibbs, Operations Manager at Minnesota Grinding. Minnesota Grinding didn’t touch the machine until it was turned on and ready to run. MachMotion had the control powered up in less than two weeks, training the operators and making parts.

Seamless integration

The interface and operation were a seamless integration and allowed a smooth transition without a learning curve. The operator was able to make parts very quickly after the new control was powered up and the grinder has been running ever since. With MachMotion’s lifetime support, Minnesota Grinding is confident in their decision to retrofit their Cincinnati centerless grinder with MachMotion.

About Minnesota Grinding

Minnesota Grinding has been in the business of precision grinding for over 50 years. They offer services of cylindrical grinding, centerless grinding, thread grinding, double disc grinding, lapping, and honing with over a hundred machines in their facility to a broad range of application such as aerospace, medical, motion components.