06 Jan How To Automate Your Spindle Warm Up

How To Automate Your Spindle Warm Up

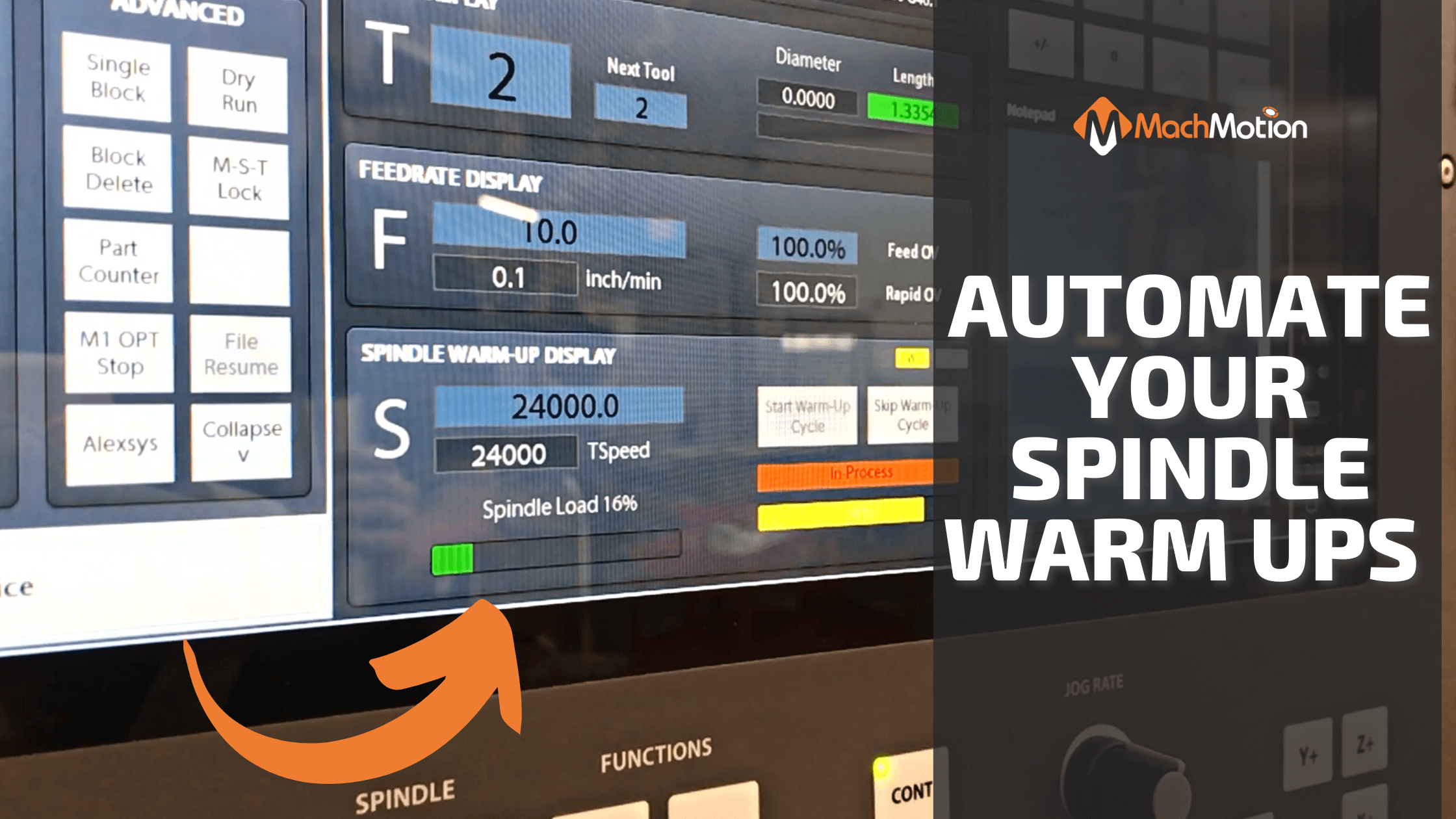

Ready to automate your spindle warm up process? Tired of writing code to manually warm up your spindles? When you upgrade your CNC with MachMotion, you can put an end to those days. The one-touch warm up feature allows you to speed up your processes and offers time savings. Automating a manual process offers the biggest gains in process efficiency. By making it easier for your operators to start cutting more easily, you will really notice the difference.

A spindle warm up is typically a manual program run prior to cutting that tells the spindle to run at a certain RPM in a dwell cycle for a set amount of time. This allows the machine, whether it be a mill, lathe, or router like in our video tutorial, to bring the bearings, axes, and grease up to temperature before you start your cutting cycle.

When it comes to spindles, having an easy and effective process for warming up will ensure that each cut cycle is as accurate as possible. We built this into our control system to help your team ensure cutting accuracy. Cold and warm temperatures will affect cutting materials. When a spindle sits idle, it needs to be warmed up properly to ensure all the bearings. By cutting before your spindle is warm, you may also wear it down prematurely or damage it. Spindles work best when they are operating at their optimum temperature.

Watch the quick 2-minute video to see how simple it is to warm up your spindle with the MachMotion 2000 series controller and our 1-touch warm up feature!

VIDEO TRANSCRIPTION:

Hey, Marcus here with MachMotion. So today I’m going to show you MachMotion’s One Touch Spindle Warm-up. You come in in the morning, doesn’t matter if it’s wintertime, summertime, you still have to warm up your spindle. Instead of going through and doing it manually just step by step and standing here for 10-15 minutes or more. With our system you can just hit this one button and it’ll start up.

There you have it, all finished. I was able to go grab a cup of coffee. From this point you can go ahead and put your material down and load in a G-Code file and start cutting. Or if you wanted to load in your material before and set your G-Code, it would automatically prompt the spindle warm up and then right after it’s done it would go ahead and start cutting. If you like what you saw please like, share, comment, and if you have a machine that you want to upgrade please get in to contact with us we’d love to talk to you!

If you’re interested in learning more about our controller upgrades for your CNC machines, click here!