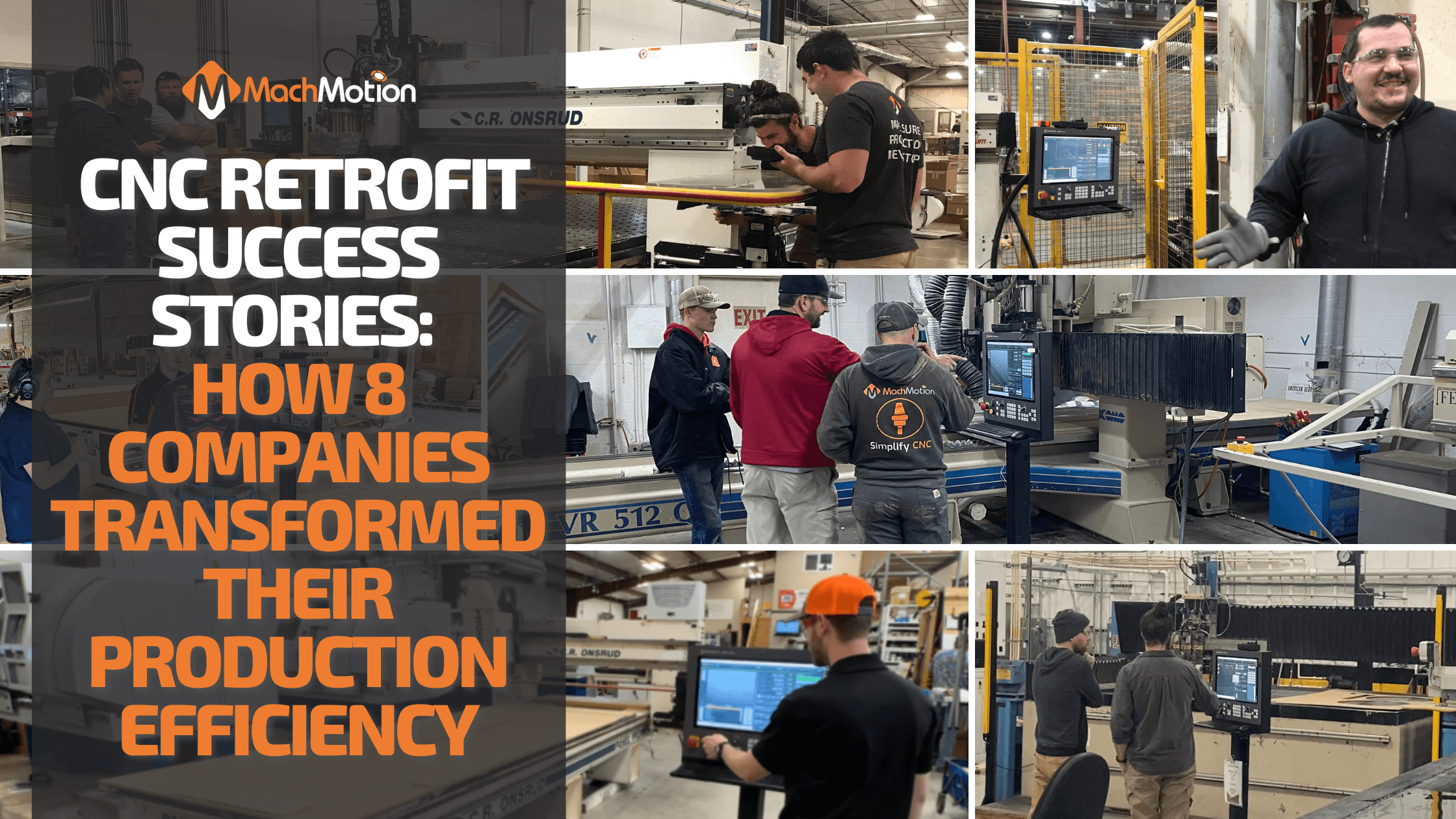

07 Aug 8 Inspiring CNC Retrofit Success Stories: How Companies Transformed Their Production Efficiency

8 Inspiring CNC Retrofit Success Stories: How Companies Transformed Their Production Efficiency

Check out how our customers have benefited from optimizing their CNC machines with a MachMotion CNC retrofit. See how these companies have reduced downtime, improved their production processes, and boosted profitability.

Having efficient and effective production processes is essential in today’s fast-paced business world. CNC machines have revolutionized manufacturing by automating the process of cutting, drilling, and milling various materials such as metals, plastics, composites, and more. However, as technology advances and businesses evolve, companies have to adapt their CNC machines to maintain their competitiveness. Investing in a CNC retrofit allows you to enjoy all the new technology with the machines you already own.

Throughout this blog, we will present real-world success stories of MachMotion CNC retrofits that have transformed production processes, reduced downtime, and relieved many headaches.

SCI Surfaces CNC Retrofit Success

Customer Story– SCI Surfaces

Specialty: Manufacturing custom granite & quartz countertops

CNC Machine Optimized: Master JetSaw 2400

Before optimizing the Master JetSaw 2400 at their facility, Cole Rush of SCI Surfaces recalls his numerous unpleasant experiences with unplanned downtime. The waterjet had experienced control and drive issues causing them to pause their production many times. It was common to experience a minimum of one hour of downtime every day. In the long run, this wasn’t sustainable to keep production going.

Cole explained “the guts of the saw were really good,” so they did not want to replace the whole machine. The cost of buying new would be very high and would require a substantial amount of effort including moving the machine they already have out of the building to bring a new one in. The company decided to contact MachMotion to explore other options to get their machine running efficiently again. After talking to our experts, they discovered they could upgrade to the latest technology without replacing the whole machine.

As a result, they would be able to keep this machine in production for years to come without the daily unpleasant downtime. Not only did they optimize their machine, but they can now keep it running for years to come. They stated they found the “perfect fit” for their machine.

Hydrosolutions of Duluth CNC Retrofit Success

Customer Story – Hydrosolutions of Duluth

Specialty: Waterjet cutting, metal forming, CNC machining, and assembling products for the aerospace, medical, and architectural industries.

CNC Machine Optimized: Jet Edge Waterjet

HydroSolutions of Duluth had a serious issue on their hands when their Jet Edge waterjet, a workhorse of their production system, failed unexpectedly. Every minute they were down meant lost revenue and delayed customers, so you can imagine the pressure they were under to find a solution.

HydroSolutions of Duluth thought they only had two options. They could either buy a brand new machine, which would cost them a fortune and come with all sorts of headaches like new electrical, pumps, rigging costs, new machine footprint, and operator training. Or, they could try to patch up their old machine with “band-Aids and bubble gum,” which was far from a long-term solution.

Dan Larson, the owner of HydroSolutions, knew there had to be a better, alternative solution out there. As a result, he contacted MachMotion and learned that many companies like his could keep the machine they love, and are familiar with, without disruption by upgrading the controls of their existing CNC machines to optimize and modernize them in an effort to save money and keep production going.

With MachMotion’s help, Dan & his team at HydroSolutions was able to complete a MachMotion upgrade on their own with a self-install package and save their Jet Edge waterjet. This prevented them from having to spend a lot more money on a brand new machine as well as from having to cope with future breakdowns.

American Gear Company CNC Retrofit Success

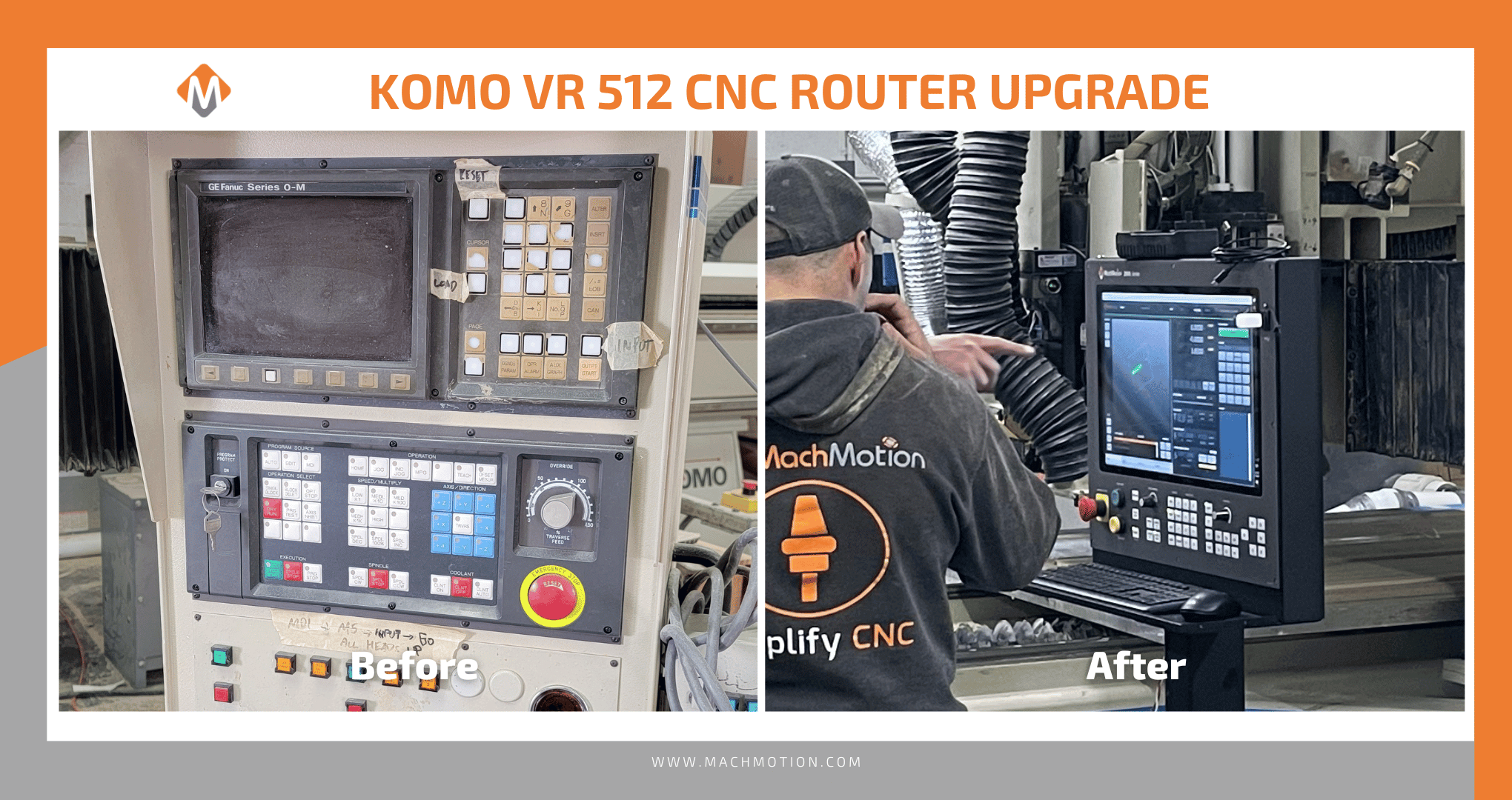

Customer Story – American Gear Company

Specialty: Snow & Surf Outdoor Equipment Manufacturer

CNC Machine Optimized: KOMO VR 512 4-Gang Spindle Router

American Gear Company, an outdoor equipment company that produces surf and snowboards in Utah, was facing a challenge when their control began giving them issues on their KOMO 4 gang spindle router. There had been numerous instances where this high-production router had unexpectedly failed, causing deadlines to be pushed and frustration among the operators.

Many companies in these situations, like American Gear Company, felt that their options were very limited. They could either buy a new machine or use temporary fixes to keep the existing one operating. However, neither decision satisfied their needs.

An expensive new machine would not only cost a fortune but would also include additional costs including new spoiler boards, rewriting programs, tooling, and rigging the move of the machines just to name a few. It also wasn’t a guarantee that bandaging their existing router would stop something else from breaking in the future.

American Gear Company’s owner, Adam, realized there had to be a better solution, so he turned to MachMotion… Adam discovered CNC optimization has improved considerably over the past few years, making it possible for companies like his, to obtain the results they want from their existing machines at a fraction of the price of a new machine.

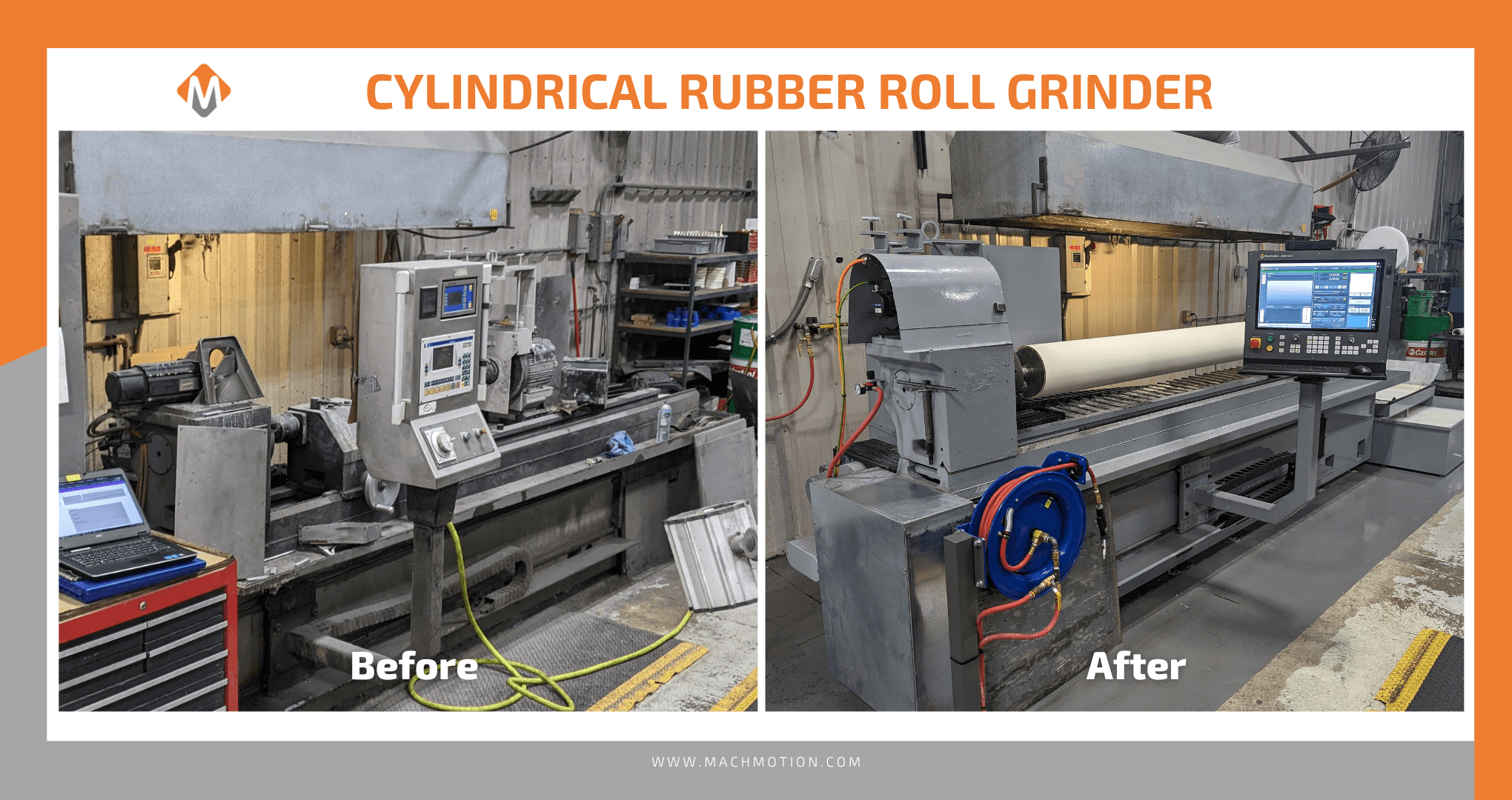

Rol-Tec CNC Retrofit Success

Customer Story– Rol-Tech

Specialty: Manufacturing custom molded parts

CNC Machine Optimized: Cylindrical Rubber Roll Grinder

Rol-Tec’s cylindrical grinder used for rubber rolls went down because of a bad control. Due to the age of the machine, it was no longer supported, and the controls were obsolete. Since they were unable to operate the machine, they could no longer keep it in production. It was taken out of production and ended up sitting idle for years.

After experiencing a successful cylindrical grinder upgraded with MachMotion on one of their other steel grinders last year, they decided to move forward with upgrading their rubber roll grinder with MachMotion. Once the machine was retrofitted and updated with the latest technology, Rol-Tec was able to get their machine back into production.

As a result of the upgrade, Rol-Tec was able to increase production, avoid the cost of a new machine, and train their operators more quickly and efficiently than ever before.

Dynatect Manufacturing CNC Retrofit Success

Customer Story – Dynatect Manufacturing

Specialty: Dynamic Equipment Protection

CNC Machine Optimized: 1994 Progressive Technologies Waterjet

In the waterjet department at one of Dynatect Manufacturing, Inc.’s facilities in Wisconsin, their team faced a significant challenge when their 1994 Progressive Technologies waterjet started experiencing controller issues. As a result, it eventually stopped working completely and had to be withdrawn from production. After investigating the problem, they discovered that the motherboard on the controller was fried, and replacement parts were impossible to find since the controller was obsolete.

They began to seek out their options for solutions and found they could either buy a new waterjet, purchase a used waterjet, or upgrade their controls. They recognized that the frame of the waterjet was still solid and that with the right upgrades, it could continue to serve the company for years to come. After researching their options, retrofitting the waterjet was their best and most cost-effective choice.

Dynatect contacted MachMotion to discuss details and what they wanted to do with their machine. They ended up deciding on a full turnkey installation with our team would be the best route for them to get their machine optimized. After our expert installation team installed their upgrade, Dynatect was back in production within a week!

Andersen Windows & Doors CNC Retrofit Success

Customer Story – Andersen Windows & Doors

Specialty: Manufacturing Windows & Doors

CNC Machine Optimized: C.R. Onsrud CNC Router

Andersen Windows and Doors had a major issue on their hands – an unreliable CNC router. The router’s AMC controller began to malfunction. Since they used this machine specifically to cut out holes in their specialty pet doors, they knew they needed to keep production going. To get those doors out on time they would need to be able to rely on this CNC router.

They reached out to MachMotion to see if they could save the CNC router they loved with a CNC machine controller upgrade. With their team’s experience, they were confident in their ability to upgrade the controls on their own. They were able to get everything installed successfully, and with MachMotion commissioning everything afterward, they were back in business and producing more doors than ever before.

Not only were they able to keep their existing CNC router up and running, but they didn’t have to shell out a ton of cash for a brand-new machine.

These real-world success stories demonstrate the benefits of investing in a CNC retrofit. Upgrading an existing CNC machine can result in increased machine speed and accuracy, reduced maintenance costs and downtime, and increased profitability. With the advancements in technology, CNC retrofits are becoming increasingly accessible and cost-effective for businesses of all sizes.

Dayton Lamina CNC Retrofit Success

Customer Story – Dayton Lamina

Specialty: Industry leader in the production of catalog and special punches, die components, die details, punch blanks, and metal-stamping tools.

CNC Machine Optimized: Toyoda GL6 OD Grinder

Dayton Lamina, a global leader in fabrication and stamping solutions, faced a challenging problem when their Toyoda GL6 OD Grinder controller became unsupported and obsolete. The search for standard maintenance parts became difficult, and finding replacement parts was almost impossible. Dawn, their Continuous Improvement Engineer, reached out to MachMotion to see if retrofitting their OD grinder was an option for them. MachMotion understood Dayton Lamina’s concerns and provided a turnkey installation that allowed the OD grinder to run at full capacity again.

After the retrofit, Dayton Lamina was able to return the machine to full production and even trained a number of new operators who had no experience with grinding equipment. They plan to upgrade more of their older equipment to be more user-friendly and easier to train in the future.

Sleepsafe Beds CNC Retrofit Success

Customer Story – Sleepsafe Beds

Specialty: Durable medical equipment products

CNC Machine Optimized: C.R. Onsrud 145G16D Panel Pro CNC router

SleepSafe Beds experienced a huge setback when their existing OSAI controller failed to function properly, leaving their C.R. Onsrud 145G16D Panel Pro CNC router inoperable. After researching their options, they decided to keep the machine and retrofit the CNC router with new controls. The company sought out an integrated solution from MachMotion. With a full turnkey install package, our expert installation team traveled to their facility in Basset, Virginia to get them back in production again.

The first step was to decommission the machine and remove all the old components, including the OSAI CNC controller, old motors, and electrical panels. Next, our team mounted all the new hardware, including the new controller, motors, servo motors & drives, and the electrical panel. The team then focused on running the cables, followed by wiring & set-up, adapting all the old wiring and updating any schematics.

Once the hardware was installed and the wiring was complete, our team powered up the machine and conducted calibration and software set-up. The team then focused on integrating the newly upgraded machine into production and cut test parts to ensure everything was running smoothly. Finally, we trained the operators on the new control, ensuring a seamless transition to the new system.

MachMotion’s turnkey install package provided a complete solution, allowing SleepSafe Beds to get back to production quickly and with the confidence that their investment was well-protected.

The CNC router retrofit on their C.R. Onsrud Panel Pro provided improved cutting accuracy, faster cutting speeds, and overall enhanced performance.

As businesses look for ways to improve their production processes and increase profitability. A CNC retrofit involves upgrading an existing CNC machine with new components, such as controllers, drives, and motors, to improve its performance and capabilities. At MachMotion, we specialize in CNC retrofits and have helped numerous businesses improve their production processes and increase profitability. Our team of experts can provide customized solutions to fit your specific needs and requirements. Contact us today to learn how we can help you take your production capabilities to the next level.

This collection of 8 CNC retrofit success stories demonstrates the power of innovation in manufacturing. Modern CNC retrofit solutions can revitalize outdated machines, resulting in remarkable results. By retrofitting, you unlock new levels of productivity, efficiency, and precision, not just upgrading machinery. Whether it’s rejuvenating legacy equipment or enhancing capabilities, these success stories show how CNC retrofits can have a tangible effect on businesses of all sizes.

As you consider your own manufacturing journey, let these stories serve as inspiration. Whether you’re grappling with outdated equipment or seeking ways to elevate your operations, CNC retrofits offer a proven path toward success. Call us at 573-368-7399 or fill out the contact form below to see how you can take action and upgrade your CNC machines before disaster strikes.