03 Feb 6 Game-Changing CNC Machine Customization Features

6 Game-Changing CNC Machine Customization Features That Modernize Your Workflow

For owners of industrial CNC machines, upgrading the controls isn’t just about doubling the life of your CNC machines —it’s about modernizing to stay ahead. That’s where MachMotion steps in. Our unique controller customization capabilities offer a seamless way to breathe new life into aging CNC machines, making them future-proof and conformable to your production needs.

These 6 key customization features of MachMotion’s CNC control systems are changing the game for CNC machine owners:

1. Preconfigured Buttons for Quick Customization Convenience

2. Dynamic Pound Variables for Precision Control

3. User Access Configuration for Security

4. Global Monitoring System for Remote Access

5. Data-Powered Production Insights

6. Machine-To-Machine Synchronization

1. Preconfigured Buttons for Quick Customization Convenience

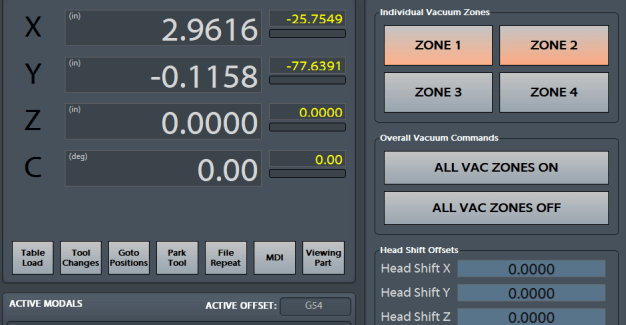

Easily design a custom screen with over 1,000 preconfigured button options accessible through easy-to-manipulate dropdown menus. This powerful feature allows you to adjust your CNC interface to meet the specific needs of your operations without requiring any programming expertise. Adjusting colors, organizing button groups, and fine-tuning Digital Read-Out (DRO) precision can all be accomplished in just a few clicks. These buttons you to implement essential functions including:

• Vacuum ON/OFF

• Dust Collection ON/OFF

• Notepad

• Calculator

• Load G Code

• Zero All

• Camera Feed

• Rotate

• Spindle Functions

• & many more!

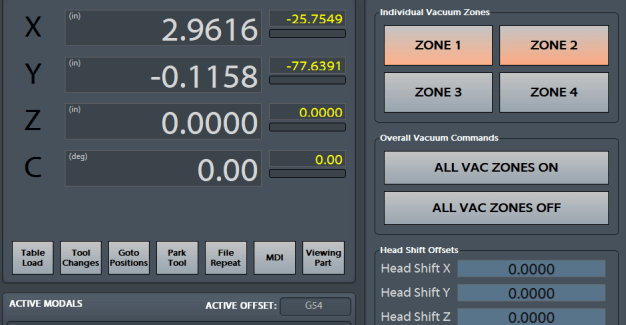

2. Dynamic Pound Variables for Precision Control

Make real-time adjustments to G-Code right on the control with pound variables. This feature allows users to modify part dimensions, offsets, and other settings dynamically during production. Imagine being able to fine-tune operations on the fly, reducing errors and improving part accuracy without having to halt production to re-program!

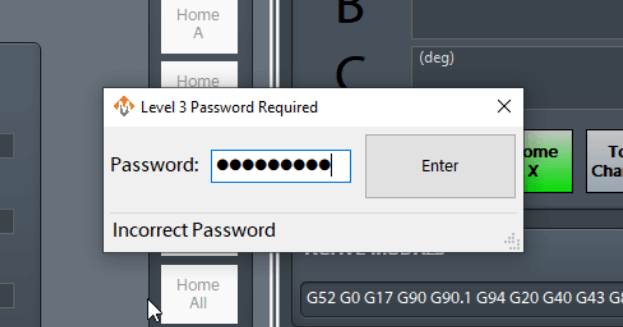

3. User Access Configuration for Security

Controlling who can access your CNC system isn’t just a precaution—it’s essential to protecting your business. With MachMotion, you get a robust three-tiered protection system that puts security in your hands. Customizable buttons and page passwords let you decide who has the authority to make critical adjustments or access sensitive machine functions.

This means no more unauthorized parameter changes, no risk of costly mistakes from inexperienced operators, and no chance of losing valuable production time to errors. With MachMotion, you can lock down your machines, secure your data, and keep your operations running smoothly.

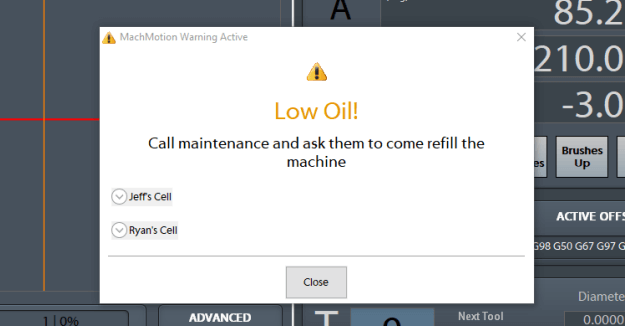

4. Global Monitoring System for Remote Access

Stay connected to your CNC machines no matter where you are. MachMotion’s global monitoring system allows secure access to machine data, real-time production metrics, and preventative maintenance alerts. Seamlessly create any user message linked to any machine function with simple clicks, making it easy for operators, maintenance, and everyone else to understand. Whether you’re at the shop or on the go, you can ensure everything is running smoothly.

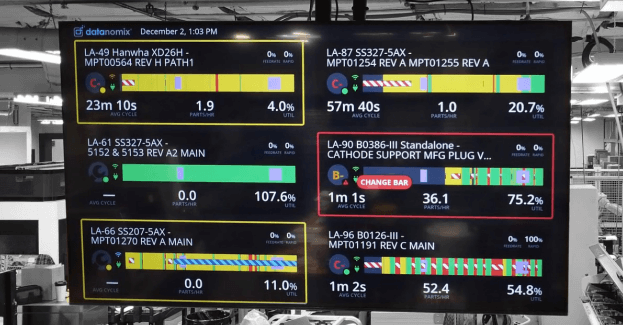

5. Data-Powered Production Insights

MachMotion’s systems are MT-Connect compliant, meaning they integrate seamlessly with third-party software for real-time production reporting. By integrating with such third-party software, you can standardize your data and generate real-time reports that provide actionable insights. Track essential metrics like parts produced per hour, operator efficiency, and machine idle time to optimize production and identify bottlenecks. With these powerful tools, MachMotion transforms your production data into a strategic advantage, helping you make informed, real-time decisions that drive profitability.

6. Machine-To-Machine Synchronization

MachMotion’s advanced Machine-to-Machine Synchronization brings Industry 4.0 readiness to your shop floor, enabling seamless communication between multiple CNC machines. With robust data logging, you can capture and analyze performance metrics across your entire operation, providing valuable insights for optimizing efficiency.

The bridge plugin allows machines to be networked effortlessly, ensuring a cohesive and integrated production environment. Additionally, the REST API interface empowers your machines to “talk” to one another, facilitating coordinated operations and even establishing restricted zones to prevent overlap or interference. These features not only enhance precision and safety but also streamline complex workflows, giving your business a competitive edge in modern manufacturing.

Future-Proof Your CNC Machine With MachMotion

MachMotion’s systems are MT-Connect compliant, meaning they integrate seamlessly with third-party software for real-time production reporting. By integrating with such third-party software, you can standardize your data and generate real-time reports that provide actionable insights. Track essential metrics like parts produced per hour, operator efficiency, and machine idle time to optimize production and identify bottlenecks. With these powerful tools, MachMotion transforms your production data into a strategic advantage, helping you make informed, real-time decisions that drive profitability.