01 Jul 3 Ways Woodworking Shops Are Losing Money with Obsolete CNC Machinery

3 Ways Woodworking Shops Are Losing Money with Obsolete Controls on CNC Machinery

Do you have CNC machinery that is running with old or outdated control systems? If so, you’re not alone. In fact, many woodworking companies experience similar issues, which can be detrimental to their business’s bottom line. In this blog post, we’ll explore the top three ways woodworking shops and CNC owners are losing money with their aging control systems and how a CNC retrofit can help to eliminate these issues.

Top 3 Ways Woodworking Shops Are Losing Money With Aging Controls:

1. CNC Machinery Downtime & Reduced Productivity

2. The Learning Curve and Inefficient Machining

3. Incompatibility with New Technology and Software

CNC Machinery Downtime and Reduced Productivity

One of the most significant ways CNC owners in the woodworking industry are losing money with their machines is through downtime and reduced productivity. Outdated or obsolete CNC controls can lead to more frequent breakdowns, harder to find replacement parts, and more demanding maintenance, resulting in longer periods of downtime. This means that production is stalled or halted completely, and businesses struggle to complete projects on time, leading to missed deadlines and lost revenue. In addition, these older controls are typically unsupported, so there’s no one to call when you are down and need help.

By retrofitting your CNC machinery with newer controls, you can reduce downtime and increase productivity. With a CNC retrofit you can upgrade your machine’s control system, which will result in a more reliable, fully supported, and efficient operation. This means less time spent on maintenance and problem solving and more time spent on production, ultimately leading to increased revenue and profitability.

The Learning Curve and Inefficient Machining

Another way CNC owners are losing money with their machines is through the learning curve and inefficient machining. Outdated CNC controls are not only hard to learn how to operate, but they also can’t keep up with the demands of modern machining. This results in slower onboarding of new operators and less accurate operations. This can also lead to wasted materials from mistakes being made, longer machining times, and increased training time, all of which can cost CNC owners a significant amount of money.

With a CNC retrofit, you can upgrade your machine’s control system to a new system that is easy-to-learn and efficient to run. This means faster onboarding and more accurate operations, which can reduce scrap rates, save on time & materials, and ultimately increase profitability.

Incompatibility with New Technology and Software

As controls age, they become incompatible with new technology and software. Outdated CNC controls may run on floppy disks and old software that is no longer supported or readily available. CNC controls running operating systems such as Windows 95, 98, XP and many others are outdated. These older control systems are typically not able to connect to a network and also lack security features that can be detrimental to your operations. They also may not be compatible with the latest software updates, resulting in an inability to take advantage of new updated features and capabilities. This can lead to missed opportunities and reduced productivity.

A CNC retrofit can address this issue by upgrading your machine’s control system to be compatible with the latest software updates. This means you can take advantage of new software features and capabilities, leading to increased productivity and profitability.

How To Upgrade CNC Machinery With MachMotion

As we’ve seen, there are several ways CNC owners are losing money with their machines due to obsolete CNC controls. With problems like downtime, reduced productivity, the learning curve, inefficient machining and incompatibility with new technology & software, these issues can cost CNC owners significant amounts of money. However, a CNC retrofit can help to alleviate these issues and save CNC owners money in the long run. By upgrading your machine’s control system, you can reduce downtime, increase productivity, and take advantage of new software features, ultimately leading to increased profitability.

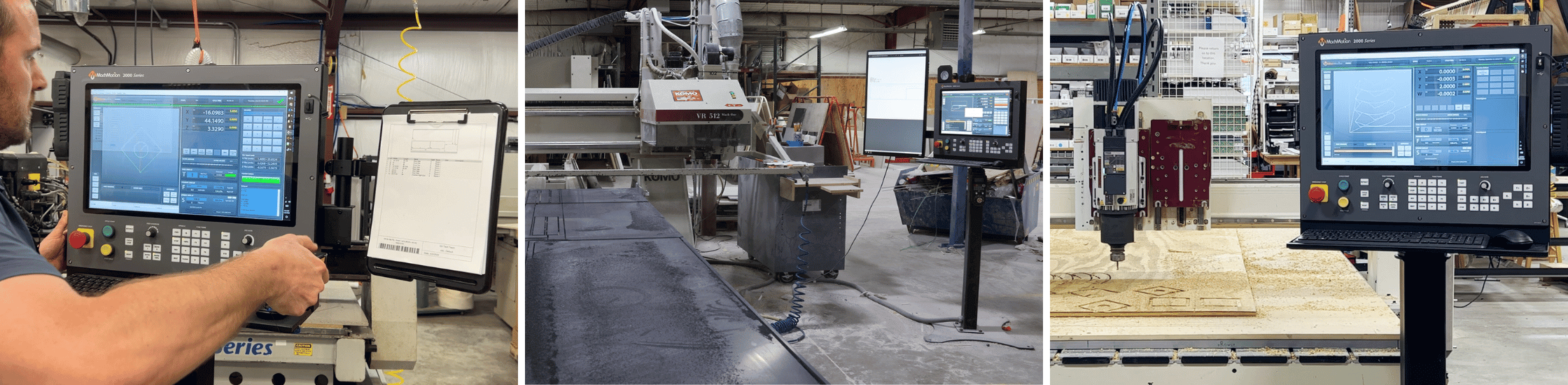

Upgrading your CNC machinery with MachMotion is a streamlined and efficient process designed to breathe new life into your existing woodworking equipment. Begin by scheduling an initial consultation with our expert team, who will assess your current CNC machinery and understand your specific needs and goals. Based on this evaluation, MachMotion will provide a tailored proposal outlining the retrofit plan, costs, and expected outcomes. Once you approve the proposal, our engineers will design a customized control system to enhance your CNC machine’s performance.

We then assemble and thoroughly test all components before shipping the retrofit kit to your location. You can choose to do a self-install or hire our expert installation team to get you up and running in as little as 1-week. Following installation, we provide comprehensive training for your operators and offer ongoing remote support for the life of the control to ensure optimal performance.

With MachMotion, upgrading your CNC machinery becomes a hassle-free experience, allowing you to maximize efficiency and extend the lifespan of your equipment. We are a full service company one phone call away for any problems with the machine. We also offer extended warranty options as well as a 20 year parts replacement guarantee.

So, if you’re experiencing any of these issues with your CNC machine, it may be time for a CNC retrofit. If you are interested in learning more about the benefits, read 10 Benefits of a CNC Router Retrofit. The solution you need to increase your profitability and take your business to the next level is right here.