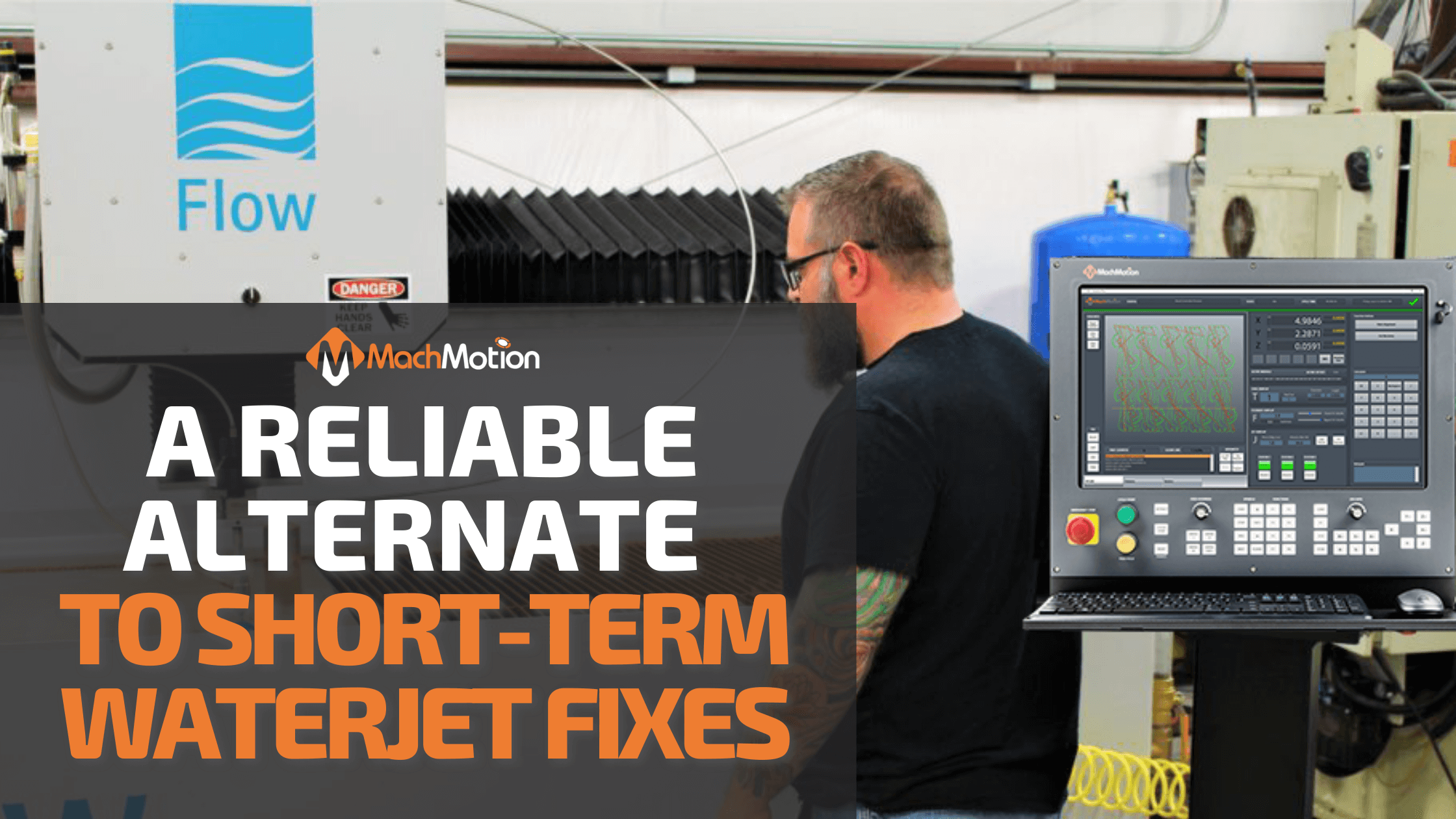

04 May Is Troubleshooting Your Flow Waterjet Costing You?

Is Troubleshooting Your Flow Waterjet Costing You? – A Reliable Alternate to Short-Term Costly Fixes

Have you considered upgrading your Flow waterjet controller?

Today many CNC waterjet machine owners are using an outdated controller for their cutting machines. Oftentimes, we encounter Flow waterjets with Delta Tau controllers and failing PMAC cards or old Yaskawa sigma drives. It is not uncommon to see machines with PCs running Windows XP, no longer supported by the manufacturer. These machines have great iron but also have outdated electronics & software, limited support and lack the functionality of modern CNC controllers. As a reliable alternative to repeatedly performing short-term fixes, the MachMotion 2000 series control is a fully integrated and supported CNC controller that can be updated as software technologies advance. Upgrade your machine to a modern CNC controller today with our turnkey waterjet controller upgrade!

If you are considering a CNC Waterjet Controller Retrofit or Upgrade for your Flow waterjet, there are a few things to keep in mind when deciding what to do next with your machine. Some of the benefits of a CNC Retrofit include:

- Cost-Effective Solution – Upgrade your Flow waterjet at a fraction of the cost of cumulative repairs or a brand new machine.

- Simple Logistics – No need to rearrange the facility to move the old waterjet out and a new one in. Mechanical, electrical, and software modifications make modern Flow waterjet upgrades easy.

- Minimal Disruption – Keep the machines in your facility that you’re already familiar with AND enjoy all the technology benefits of a new machine.

- Low Downtime – Efficient, expert installations allow your team to quickly get back to production with little interruption.

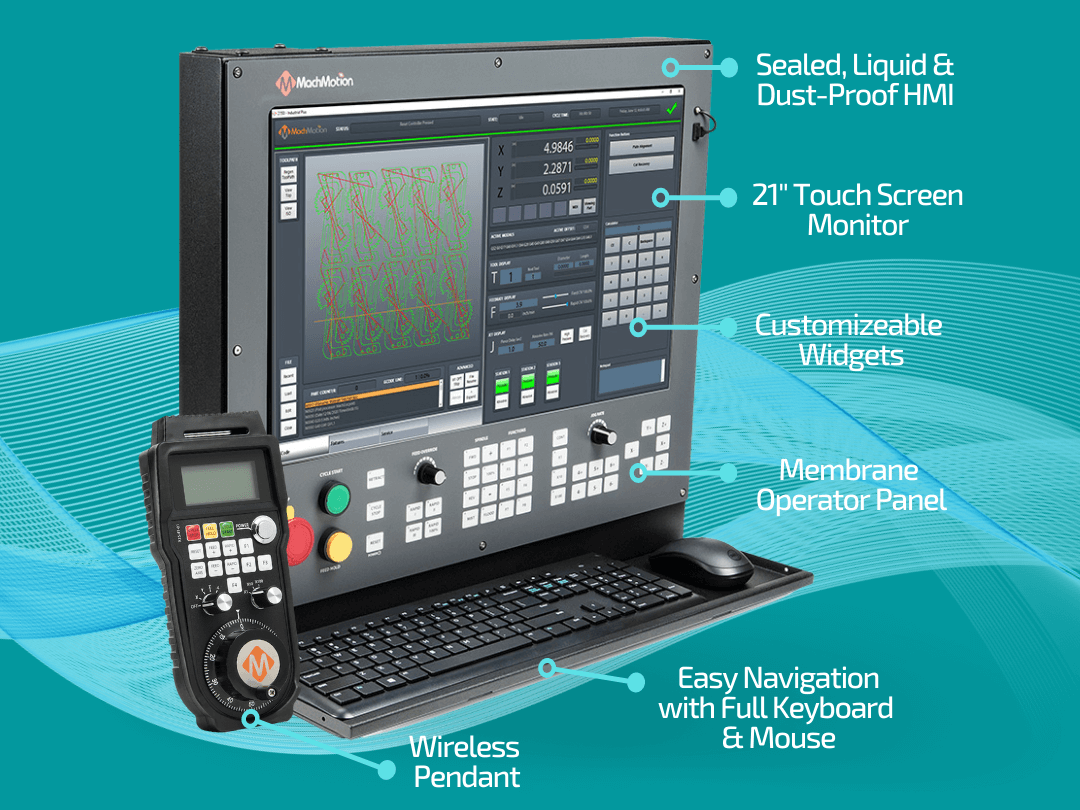

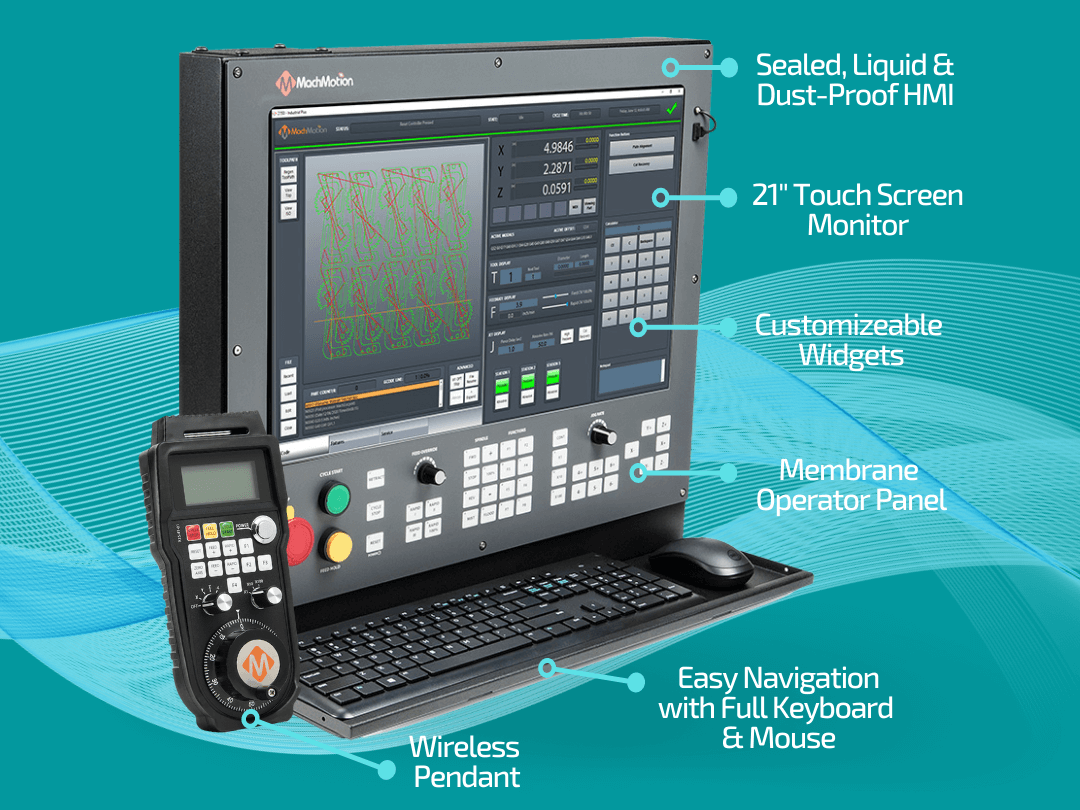

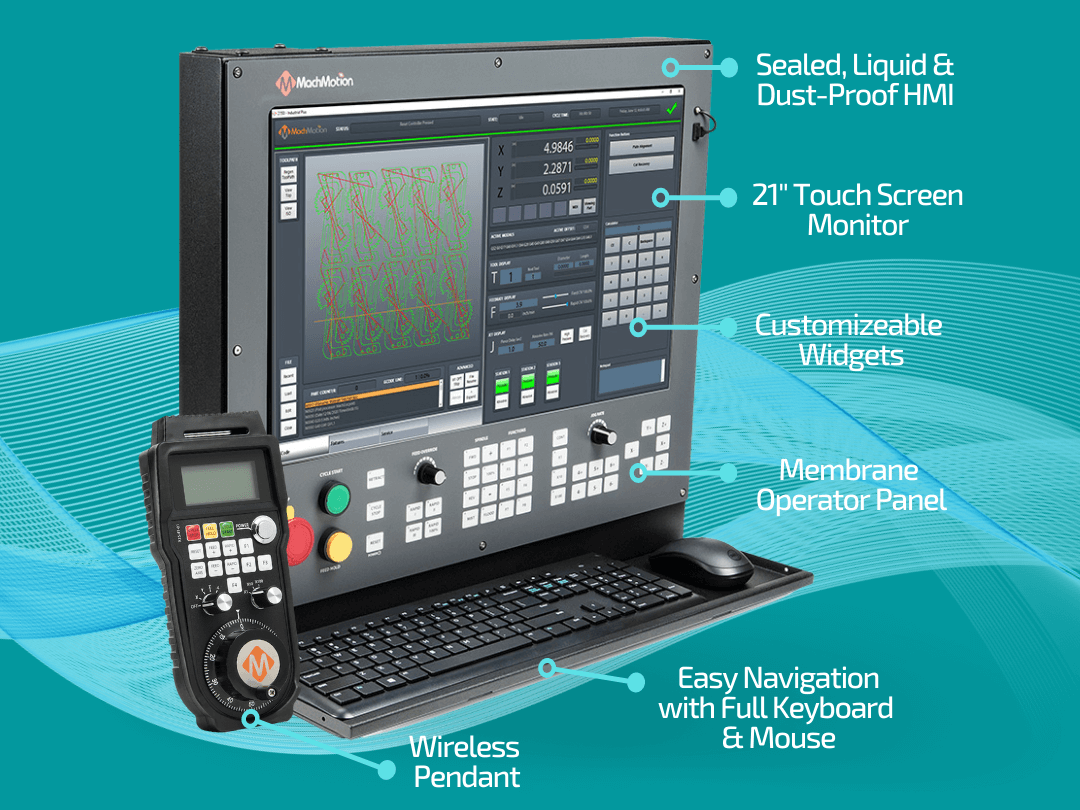

Consider MachMotion’s 2000 Series Controller Upgrade for your Flow Waterjet!

We strive to support you in keeping your equipment running and in production for years to come. Since focusing on upgrades and retrofits for 20+ years, we recognize the problems & interruptions that come with owning a Flow waterjet. At MachMotion, we focus on delivering up-to-date and reliable technology! Our team can help you determine if your machine(s) are good candidates for an upgrade. With a MachMotion CNC controller consultation for your Flow waterjet, we can guide you through the process and what it can look like for your equipment.

Whether you choose a self-installation, where we ship you a fully functional system for your team to install with our remote technical support, or a full turnkey installation where our technicians come on sight to handle the installation and train the operators. Our turnkey installs are covered under our production-ready guarantee. Every controller package includes a 1-Year Warranty and FREE Remote Support for the lifetime of the control.

Remote Support for the Lifetime of the Control –

We offer lifetime technical support via phone, email, and remote login (if internet access is available at the control) at no extra charge. Minimize shop floor disturbance, frustration & downtime by upgrading your system controls for your team. Get in touch with us today!

1-Year Parts Warranty –

We guarantee all new products to be free from manufacturer defects for a period of one year from the date of purchase. Products that prove to be defective under normal conditions and proper use, during the warranty period, will be repaired or exchanged free of charge.

Production-Ready Guarantee –

(included with MachMotion’s Installation Service) – We are confident in our products & services — We guarantee our workmanship and if anything fails after the first 90 days of our upgrade, we will come on-site at no cost to you. We will not invoice for the second installment of your order until your machine is up and running!

Evaluate Your Flow Waterjet With A Machine Health Inspection

Flow waterjets are high-quality CNC machines. Typically, we see their good iron frame outlast their controls. It’s not uncommon to see Flow waterjet controls upgraded a couple of times in a lifespan. If your controller is showing signs of age, it’s time to take a look at what you are spending on repairs and upkeep. It is common to struggle to find replacement parts for legacy Flow waterjets. They are not readily available and can cause you to be down for longer than necessary. This can cause problems with production and keeping promised dates to customers.

If you are concerned about your Flow waterjet’s mechanical condition, ask for a machine health inspection from the experts at MachMotion.

When performing a machine health check, our team will verify the condition of ball screws and backlash, linear guideways, lube system, etc. You should fix any mechanical issues discovered during a health inspection prior to upgrading the controls. This will not only maximize performance, but it will also upgrade your operator’s controller experience. Costly repairs aren’t your only option when your Flow waterjet stops working or is becoming unreliable. Upgrading to new controls as well as replacing any worn mechanical components will give your Flow waterjet extended years of reliable service. Making the right decisions now can ensure your company’s future success.

Flow Waterjet Cutting Technology for Manufacturing

Flow Waterjet is one of the leading manufacturers of one of the most versatile technologies on the market, waterjet cutting. Their waterjet machines come in all different sizes and configurations. Flow Waterjet is committed to providing high-quality industrial shape cutting machines. A quote from their website reads “Whether you are cutting the same thing every day, or changing materials to meet customer demands, a Flow waterjet will get your work done.” Their safe and high-performance solutions make them a popular choice among many industries such as Aerospace, Automotive, Energy, Oil & Gas, Transportation, Agriculture, and more!

Long-Lasting, High-Quality Shape Cutting Machines

Flow Waterjet is an industry leader in shape-cutting technology. Their equipment is utilized by companies of all sizes around the world for production, serving a variety of applications. Their line of CNC waterjet machines is one of the most reliable machines available on the market today. There is no question that Flow Waterjet will remain a leading manufacturer of CNC waterjet cutting machines for many years to come.

Flow Waterjet Machine Models

Rather than scrapping a good flying bridge or gantry waterjet, you can give it a second life with MachMotion! Contact us today – From our initial conversation and a few photos of the waterjet, we can tell you what is available for your machine, how long it will take, and the cost of doing the retrofit. We provide you with a written proposal, so you know what you are getting in your upgrade package. You can contact us at 573-368-7399 and we will be happy to speak with you and help you decide if upgrading your controller is the best direction for your waterjet.

Learn more about our CNC waterjet controller upgrades here.

Below are some of the Flow waterjet cutter models that would be good candidates for a MachMotion CNC controller upgrade:

FLOW MACH 700

FLOW MACH 500

FLOW MACH 4 3020B

FLOW MACH 4C

FLOW MACH 4C 4030 XD

FLOW MACH 3 4020B

FLOW MACH 3 3020B

FLOW MACH 300 2015

FLOW MACH 300 3015

FLOW MACH 300B

FLOW MACH 200 1313

FLOW MACH 200 3020

FLOW MACH 200 4020

FLOW MACH 200 7320

FLOW MACH 2 1313B

FLOW MACH 2 2013B

FLOW MACH 2 4020B

FLOW MACH 2B 2031B

FLOW MACH 2 2020C

FLOW MACH 2 2030C

FLOW MACH 2C

FLOW M2B 1313B

FLOW I-6012

FLOW BENGAL

FLOW IFB

FLOW M100-4020

FLOW WMC2-4030