06 Mar PARAMETRIC PROGRAMMING

PARAMETRIC PROGRAMMING

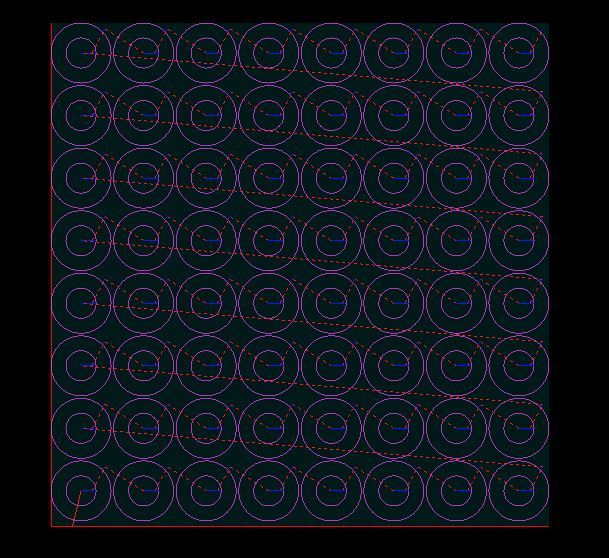

We had a customer request for a program that could nest a number of user defined washers.

Parametric programming is like having an additional programing language at your finger tips, right inside your g-code. When trying to program families of parts or custom user canned cycles, programming with variable can save an immense amount of time. There are several different versions. The most popular is Custom Macro B (used by Fanuc and Fanuc-compatible controls). Others include User Task (from Okuma), Q Routine (from Sodick), and Advanced Programming Language [APL] (from G& L). Programming with variables is standard on MachMotion controls. Macro B (extended variable control like Fanuc) is included standard on all VMC/turn controls.

What is it? Try simply setting a value to a variable in the MDI line: #100 = 1

If your control doesn’t give you an error, you have the feature enabled. Again, this is standard on all MachMotion controls.

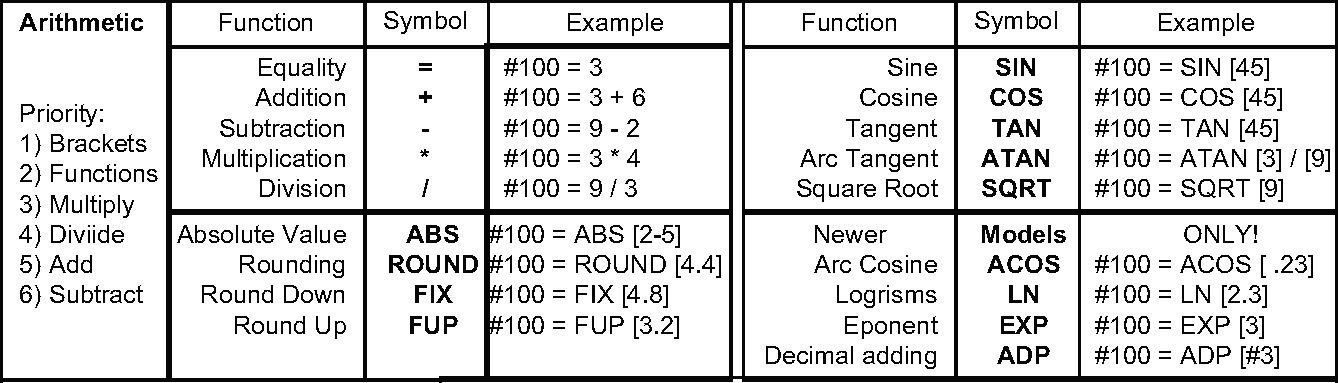

You can also program arithmetic inside brackets. Available functions include:

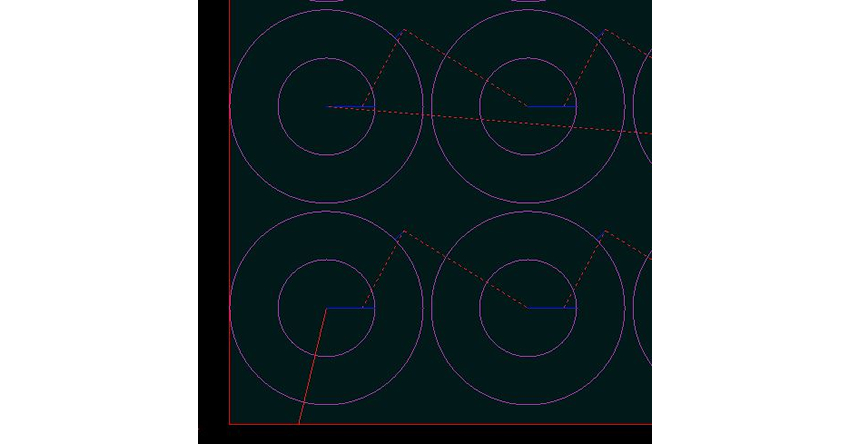

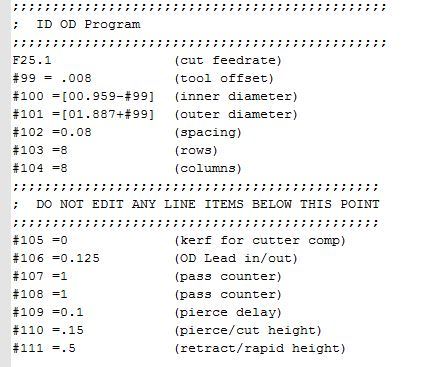

We had a customer request for a program that could nest a number of user defined washers. Based on the variables settings, the size, spacing, and number of parts can change. It even includes options to set kerf, lead-in/out size and pierce delay/height for use on a water jet.

How could you use this? Many companies have work everyday that could be done with variable programming and save time. Do you cut the same types of parts often, only changing the size? Or do you need to quickly change the number of parts in a given file?

Click here for the whole program. (right-click and select “Save As” to download)