Get an upgraded CNC OD/ID Cylindrical Grinder control with all the latest technology at ⅓ the cost of a new machine.

- Decrease setup time with built-in conversational grind cycles.

- Get a machine control that works for you! Build on an expandable foundation so when your market changes, you won’t have to worry about getting a new machine.

- Run with confidence! All MachMotion upgrades include FREE support for the lifetime of the control.

Save Time and Money

- Don’t get left behind with archaic technology! Controls become outdated, but a machine’s iron is designed to last nearly forever.

- Reusing all your current tooling, part fixtures, part setups, and grinding wheels saves thousands!

- The latest technology – Integrated SBS Acoustic Gap / Crash protection – improves cycle times and protects against potential crashes.

- Maximize uptime by maintaining the machine your team already knows.

- Watch the video to learn more!

Simplify Your Process

- A modern control is easier to use and reduces the onboarding time for your team.

- Typically, an operator is back making parts in 2-4 hours after an upgrade.

- MachMotion’s simplified conversational interface makes it easy for anyone to program any part.

Choose a Company that Will Stand Behind their Products

- We offer world-class support that reduces downtime and saves you money.

- Each MachMotion product has a team that stands behind it.

- When you call MachMotion, you can talk to a live, friendly technician who can remotely access everything in your control.

- Select the support package that works best – from the free 4-hour call back guarantee to the paid 15-minute call back guarantee.

DON’T SCRAP A QUALITY MACHINE

No system control is designed to last forever, but that doesn’t mean you have to scrap the whole machine. When your system becomes unreliable or stops working altogether, buying a new (or used) machine isn’t your only option. Instead, minimize disruption, frustration and downtime by upgrading your system controls. Read more

When you opt to upgrade, you get to keep the machine you’re already familiar with AND enjoy all the same technology as a new machine.

At a fraction of the cost of a new machine, and far less hassle than buying a used machine, why wouldn’t you want to upgrade?

CHOOSE A COMPANY THAT WILL STAND BEHIND THEIR PRODUCTS

At MachMotion, we’re committed to ensuring your success. Upgrades are our main business, so we are experts at what we do. By partnering with us, you have guaranteed access to world-class customer service for the life of the control. Read more

We are a family-owned business that places our values at the forefront of everything we do, earning the trust of some of the biggest names in manufacturing. We would like to earn your trust, too, and plan to do it by offering you the highest quality of service from start to finish.

See What Others Are Saying

See What Others Are Saying

See What Others Are Saying

See What Others Are Saying

Finance Your OD/ID Cylindrical Grinder Retrofit

With thousands of upgrades in the market, and trusted by companies including:

Installation

Turnkey Install:

We’ll do it all. Just point us to your machine and let our experienced technicians do the rest.

Ship Your Machine:

We’ll pick up your machine, upgrade it and then ship it back ready for production!

Onsite Commissioning:

After you mount the new CNC control, motors, and electrical enclosure to your machine, we will come to your facility to finish the installation and train your operators

Self-Install:

With basic electrical skills and minimal mechanical design and fabrication, you can install this kit yourself!

Features & Benefits of an OD/ID Cylindrical Grinder Retrofit

Minimize Downtime with Remote Log In Support

Minimize Downtime with Remote Log In Support

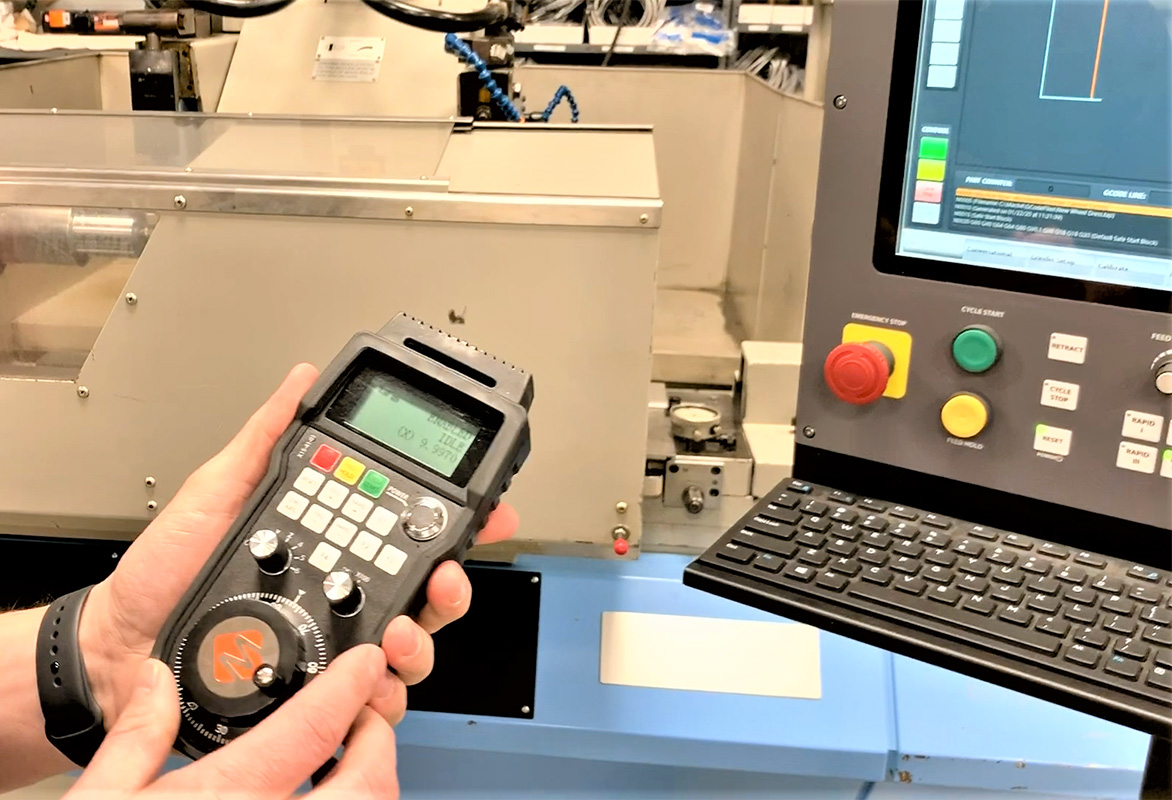

Smart, Simple, Conversational Part Programming

Smart, Simple, Conversational Part Programming

- 50% time-savings with conversational vs. programing with G-Code.

- If an operator has a grinding background, we can teach them to grind a part in 30 min.

- You don’t need to know G-Code to program parts in the CNC.

- Operators have ready-to-go, visual grind cycles.

Speed Up Your Process with a Powerful Control

Grind Wheel-Wear and Diameter Tracking

Grind Wheel Wear and Diameter Tracking

- Wheel diameter are tracked between dresses – no extra time needed for setup.

- Cylindrical grind cycles pre-programmed in the controller.

- Dress positions automatically adjust.

- Grinding wheels geometry easily saved in controller. This will save the operator from having to re-enter data.

- Operators can save over 100 grind wheels as “Tools” and call them up any time.

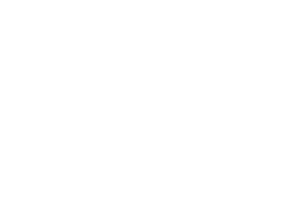

![]() Wireless Pendant Improves Setup Time

Wireless Pendant Improves Setup Time

- Pendant allows for the operator to get up close.

- Cycle Start, Cycle Stop, Feed Hold.

- Zero-axis position

- MPG Jog Increments – X1, X10, X100.

- Magnetic back to place it in a convenient location.

Reduce Training by Simplifying Your Process

Reduce Training by Simplifying Your Process

Cycle Optimization Hardware Integration

Cycle Optimization Hardware Integration

- Acoustic sensor/gap elimination – Quickly get to grinding the part and save time.

- Acoustic sensor/crash detection – Detect a crash and e-stop to minimize machine damage.

- In-process gauging head options – Grind a part to size no matter the wheel wear.

Probing/Flagging system – Simplifies setup and ensures accurate shoulder positioning.

Add a Collaborative Robot for Machine Tending

Add a Collaborative Robot for Machine Tending

- Stay competitive by installing a collaborative robot.

- Robots rarely call in sick and leave you behind in your orders.

- Easy to program and incredibly precise.

- MachMotion offers turnkey installation.

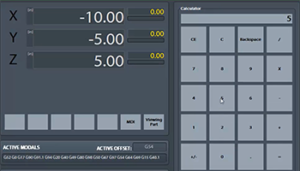

Personalize Your Control for Your Process

Personalize Your Control for Your Process

- Want a calculator on the screen? Just add it!

- Add your favorite functions to the main screen.

- Lock users out of specific screens or tabs.

- Make the screen as lean or as advanced as you need it.

Take Full Advantage of Your OD / ID Grinder

Take Full Advantage of Your OD / ID Grinder

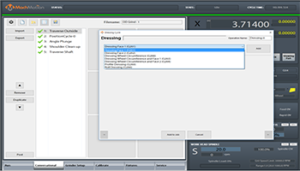

Conversational Dressing Options

Conversational Dressing Options

- 2-axis coordinated dress cycles.

- Single point profile dressing the wheel.

- Diamond rotary dresser (roll form dressing).

- Dress complex profile – Single-point dress shape into the wheel.

Sample Grinder Cycle Programing Options

- Plunge grind cycles, single- and two-axis.

- Various traverse grind cycles, infeed left, right or both ends of traverse.

- Grind dress cycles.

- To see full list of cycles, contact MachMotion.

Documentation

GET A QUOTE!

and start your OD/ID Cylindrical Grinder Retrofit with one of our sales engineers.

REQUEST A QUOTE

One of our highly-trained sales engineers will work with you to assess your needs and deliver the best possible solution, at about a third of the cost of a new machine.

ARRANGE YOUR INSTALL

Our turnkey solutions make it easy for you to get back up and running quickly. Whether you opt for a self-install or have our team on-site, we’ll help make sure your upgrade is stress-free.

RUN WITH CONFIDENCE

You can rest easy knowing that not only is your MachMotion control one of the best on the market, it comes with lifelong, world-class support. When you need us, we’re only ever a phone call away.

Call me at (573) 368-7399 or enter your name and number here and I’ll get back with you on your OD/ID cylindrical grinder retrofit within a few business hours.